Masterfil Automatic Volumetric Filler

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Up to 4,500 Containers per Hour

Product Specification:

- Fill volumes from 250ml to 30L.

- Exceptional accuracy of up to ±0.2% reduces waste.

- A choice of between 2 - 12 filling heads.

- Add extra heads to meet increased output requirements.

- Durable and robust, to endure the harshest environments.

- Versatile; nozzles can be programmed to dive and rise whilst filling, fill into neck or remain above neck.

- ‘No container, no fill’ sensing reduces waste and saves money.

- Storing multiple filling profiles increases efficiency on line throughputs.

- Easy recall of container fill profiles de-skills the machine operation.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

Please Note: This machine can be made ATEX compliant for flammable products.

Masterfil Automatic Flowmeter Filler

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Up to 4,500 Containers per Hour

Product Specification:

- Fill volumes from 250ml to 30L.

- Exceptional accuracy of up to ±0.2% reduces waste.

- A choice of between 2 - 12 filling heads.

- Flexible; add extra heads to meet increased output requirements.

- Durable and robust, to endure the harshest environments.

- Versatile; nozzles are adjustable to fill foaming and non-foaming products with variable speed filling capacity.

- Minimal down time between liquid and container changeover.

- Storing multiple filling profiles increases efficiency on line throughputs.

- Easy recall of container fill profiles de-skills the machine operation.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

Please Note: This machine can be made ATEX compliant for flammable products.

Response Automation Base

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Product Specification:

- Fast filling, up to 60 containers per minute.

- Fill volumes from 5ml to 1L.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Fills bottles, jars and screw top vials.

- Pneumatic cut-off nozzles ensure a clean fill with no dripping.

- Optional infeed and outfeed tables.

- Incorporates up to four Response Benchtop Fillers, which can also be independently used if required.

- Converts from an 8-head automatic filler into <4 benchtop filling machines within just 30 minutes

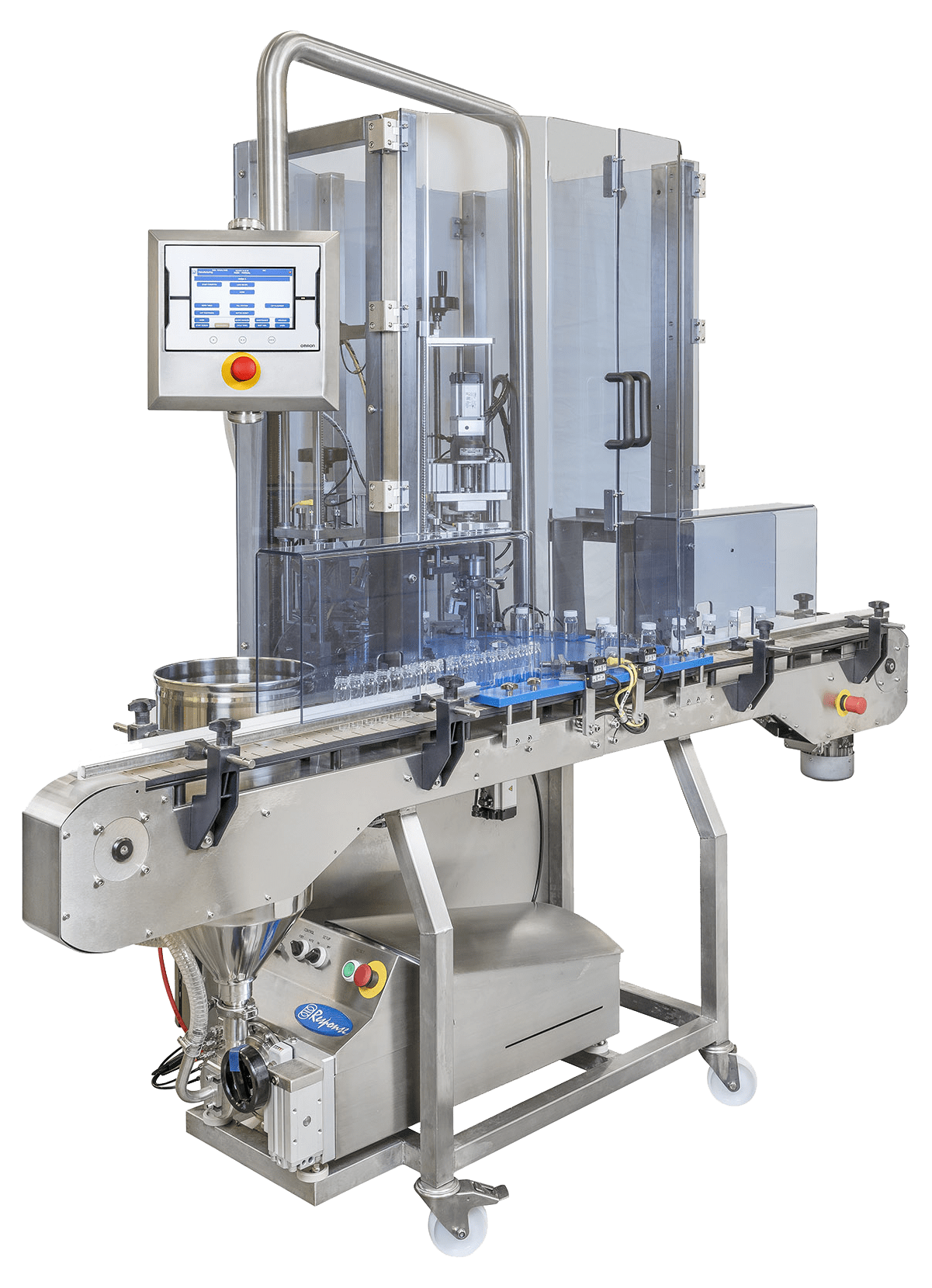

Response Monobloc 250 Filler & Capper

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Make the Most of Your Space

Product Specification:

- Fast filling and capping, up to 35 containers per minute.

- Fill volumes from 3ml to 250ml.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Compact, space-efficient footprint.

- Fills bottles, jars and screw-top vials.

- Easy-to-use intuitive HMI touch screen controls for your operator.

- Quick and easy to change parts from one fill-size container to another.

- Incorporates the Response Benchtop Filler, which can also be independently used if required.

Can include the following elements to give a complete turnkey packaging line:

In-feed table; Bottle blower; Filler; Automatic cap placement; Capper; Labeller; Collection table.

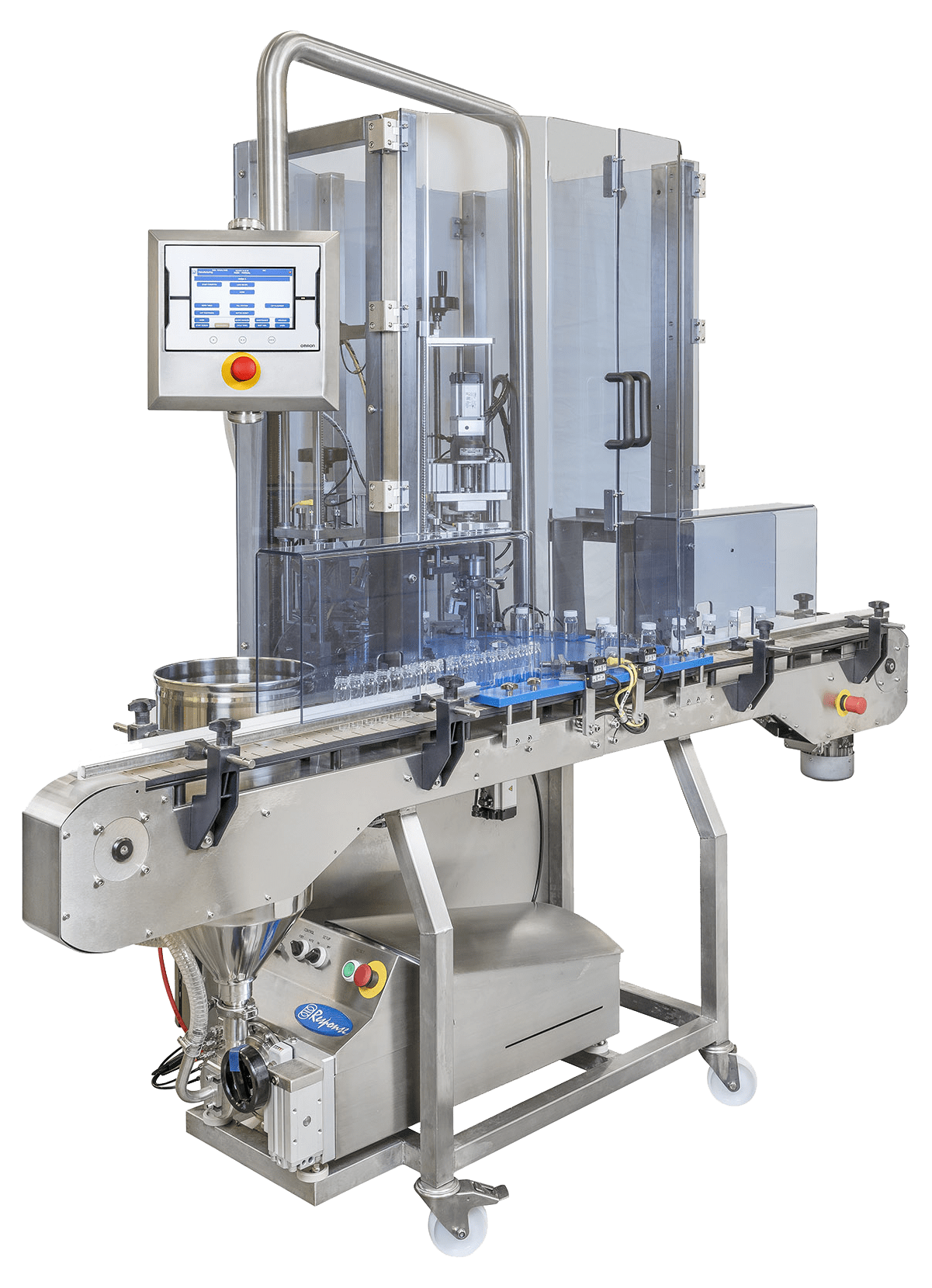

Response Monobloc 1000 Filler & Capper

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Optional Vacuum Capping

Product Specification:

- Fast filling and capping, 15-25 containers per minute.

- Fill volumes from 100ml to 1L.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Compact, space-efficient footprint.

- Fills bottles, jars and screw-top vials.

- Easy-to-use intuitive HMI touch screen controls for your operator.

- Quick and easy to change parts from one fill-size container to another.

- Optional capping under vacuum, to reduce oil leakage from mixtures such as all Nut Butters. This ensures that the product will always arrive with customers in optimum condition.

- Incorporates the Response Benchtop Filler, which can also be independently used if required.

Can include the following elements to give a complete turnkey packaging line:

In-feed table; Bottle blower; Filler; Automatic cap placement; Capper; Labeller; Collection table.

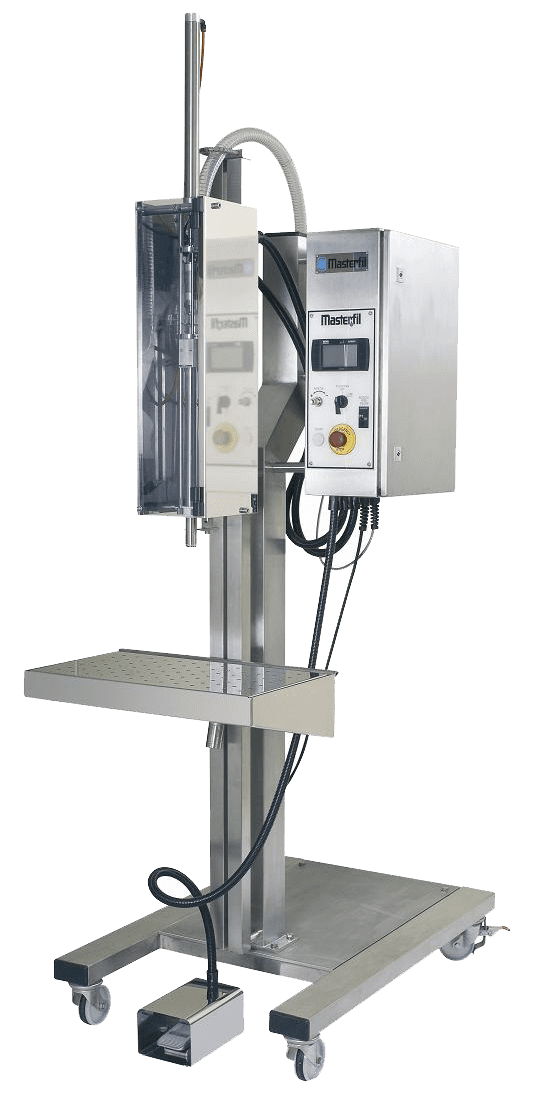

Masterfil Semi-Automatic Volumetric Filler

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Up to 720 Containers per Hour

Product Specification:

- Fill volumes from 200ml to 5L (up to 30L with multi-shot).

- Exceptional accuracy of up to ±0.2% reduces waste.

- Durable and robust, to endure the harshest of environments.

- Versatile; nozzles are adjustable to fill foaming and non-foaming products with variable speed filling capacity.

- Quick product and container changeover minimises production downtime.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

- Can be specified with one or two filling heads, single or double acting product cylinders, and a remote nozzle for filling containers on pallets.

Please Note: This machine can be made ATEX compliant for flammable products.

Masterfil Semi-Automatic Flowmeter Filler

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Up to 720 Containers per Hour

Product Specification:

- Fill volumes from 500ml to 5L.

- Exceptional accuracy of up to ±0.2% reduces waste.

- Durable and robust, to endure the harshest of environments.

- Versatile; nozzles are adjustable to fill foaming and non-foaming products with variable speed filling capacity.

- No pistons; quick product and container changeover to minimise production downtime.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

- Can be specified with one or two filling heads.

Please Note: This machine can be made ATEX compliant for flammable products.

Masterfil Bench Height Weigh Scale Filler

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Up to 720 Containers per Hour

Product Specification:

- Fill volumes from 1 - 60kg nominal.

- Exceptional accuracy of up to ±0.2% reduces waste.

- Durable and robust, to endure washdown, hazardous or other hostile environments.

- Versatile; nozzles are adjustable to fill foaming and non-foaming products with variable speed filling capacity.

- No pistons; quick product and container changeover to minimise production downtime.

- Ideal for those who wish to minimise the use of cleaning fluids.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

- Can be specified with one or two filling heads.

- Fill accuracies comply with DOT weights and measure requirements (DTI Certification No 2001/15).

Please Note: This machine can be made ATEX compliant for flammable products.

Response Bag/Pouch Filler & Sealer

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Time-Efficient Fast Filling

Product Specification:

- Fast filling, up to 10 bags/pouches per minute.

- Fill volumes up to 500ml.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Includes a bag-blowing station, diving cut-off nozzle, hot-jaw sealing station and eject station.

- The incorporated Response Benchtop Filler can be easily removed at any time, to use as a stand-alone machine for filling other containers.

Response Benchtop Filler

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Delivery Within Days

Product Specification:

- Fast filling, up to 40 containers per minute.

- Fills bottles, jars, tubes, vials, syringes, tubs, pots and more.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Fill volumes from 3ml to 1L.

- Fully strip for cleaning in as little as 3 minutes.

- Choose from one or two filling heads.

- Versatile; interchangeable nozzles available for different products, including liquids, oils, gels, creams, pastes and thick products with particulates.

ATEX Response Benchtop Filler

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Delivery Within Days

Product Specification:

- CAT II B G c T 4 (135 Degrees Celsius) filling machine.

- Suitable for use in Zone 1 & Zone 2 applications.

- Made with ATEX certified pneumatic components.

- Well-engineered solutions to avoid static build up.

- Good earthing is ensured via an Earth Point at the rear.

- The hopper comes with a lid to reduce fume release.

- Various seal and O-ring options, which we will assess to ensure compatibility with your product.

- Fast filling, up to 40 containers per minute.

- Exceptional accuracy of up to ±0.25% reduces waste.

- Fill volumes from 3ml to 1L.

- Fully strip for cleaning in as little as 3 minutes.

- Versatile; interchangeable nozzles available for different products, including liquids, oils, gels, creams, pastes and thick products with particulates.

- Compliance peace of mind: we have lodged a technical file (09XT005) with an approved body.

XYZ Distributor

Reduces Waste, Increases Profitability

Make the Most of Your Space

Delivery Within Days

Product Specification:

- Combines with our Accuramatic Peristaltic Dispensing Unit (available to purchase separately).

- Fills bottles, vials and nested syringes.

- Quick and efficient filling, up to 36ml per second.

- Exceptional filling accuracy of up to +/-0.5% reduces costly product waste.

- Compact space-efficient footprint.

- Infallible hygiene levels; the liquid only comes into contact with a length of silicone tubing, which will withstand repeated sterilisation. This produces a completely closed system, to eliminate the risk of cross contamination.

Please Note: Maximum container height 200mm. Minimum neck diameter 6-8mm.

Accuramatic Peristaltic Dispensing Unit

Reduces Waste, Increases Profitability

Make the Most of Your Space

Delivery Within Days

Product Specification:

- Fill volumes 1 - 1,000ml.

- Quick and efficient filling, up to 36ml per second.

- Exceptional filling accuracy of up to +/-0.5% reduces costly product waste.

- Combines with the XYZ Distributor to fill bottles, vials and nested syringes, or the Filling Jig for ampoules.

- Compact space-efficient footprint.

- Can be operated by hand, foot switch, or be left to cycle automatically.

- Infallible hygiene levels; the liquid only comes into contact with a length of silicone tubing, which will withstand repeated sterilisation. This produces a completely closed system, to eliminate the risk of cross contamination.

- Bacteriological inline filtration can be performed at the outlet side of the pump.

Choose from 3 filling modes:

– Braked stop

– Soft stop

– Stop with suck back

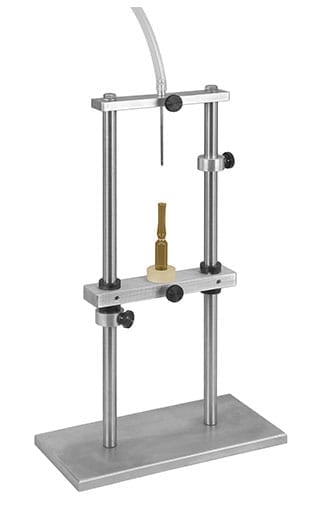

Ampoule Filling Jig

Reduces Waste, Increases Profitability

Simple & Intuitive to Use

Delivery Within Days

Product Specification:

- For use with the Accuramatic Peristaltic Dispensing Unit.

- Ensures clean filling, without wetting the ampoule wall where it is to be sealed.

- Exceptional filling accuracy of up to +/-0.5% reduces product waste.

- Hygienic, durable metal construction.

- Compact design: 210 x 105 x 345 mm.

- Operation: the ampoule is placed in a custom made holder and raised by hand to a predetermined stop, when the needle will be centred inside the container

Masterfil Semi-Automatic Flowmeter Boom Filler

Durable & Robust

Reduces Waste, Increases Profitability

Improved Operator Safety & Comfort

Product Specification:

- Fill volumes from 10L to 1,000L.

- Exceptional accuracy of up to ±0.2% reduces waste.

- Approximate output 200L per minute.

- Versatile; the swinging boom arm is also height adjustable to improve operator safety and comfort.

- No pistons; quick product and container changeover to minimise production downtime.

- Suitable for low to high viscosity liquids.

- Hygienic 316L stainless steel / PTFE contact parts.

- Fill 2 pallets side by side.

- Add a gravity or roller driven conveyor to automate infeed and outfeed of pallets/containers.

- Normally used to fill drums, IBCs and other large volume containers; our customers also often use this to fill smaller containers as a reliable back-up to other machines.

Please Note: This machine can be made ATEX compliant for flammable products.

TGM S420 Tube Filler & Sealer

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Up to 4,200 Tubes per Hour

Product Specification:

- Highly efficient automatic filling, closing and ejection.

- Exceptional output, up to 4,200/h for metal tubes, 3,200/h for polyethylene or laminate tubes.

- Metal tubes 10 - 42mm diameter,

50 - 240 mm length. - Polyethylene/laminate tubes 10 - 50mm diameter, 50 - 240mm length.

- Hygienic crevice-free surfaces and lubricant-free operation.

- Tube print orientation and sensor to detect tube right way up, minimises waste.

- Motors and machine drive below working table to ensure operator safety.

- Fold and roll crimping system for closing metal; polyethylene/laminate tubes sealed by hot air or hot jaws.

TGM B600 Tube Filler & Sealer

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Up to 5,000 Tubes per Hour

Product Specification:

- Highly efficient automatic tube filling, closing and ejection.

- Exceptional output, up to 5,000/h for metal tubes, 4,000/h for plastic or laminate tubes.

- Metal tubes 10 - 42mm diameter,

50 - 235 mm length. - Plastic/laminate tubes 10 - 50mm diameter,

50 - 235mm length. - Hygienic crevice-free surfaces and lubricant-free operation.

- Tube print orientation and sensor to detect tube right way up, minimises waste.

- Motors and machine drive below working table to ensure operator safety.

TGM B620 Tube Filler & Sealer

Faster Filling, Higher ROI

Reduces Waste, Increases Profitability

Up to 6,000 Tubes per Hour

Product Specification:

- Highly efficient automatic tube filling, closing and ejection.

- Exceptional output of up to 6,000/h for metal tubes, 4,800/h for plastic or laminate tubes.

- Metal tubes 10 - 42mm diameter,

50 - 240 mm length. - Plastic/laminate tubes 10 - 50mm diameter,

50 - 240mm length. - Hygienic crevice-free surfaces and lubricant-free operation.

- Tube print orientation and sensor to detect tube right way up, minimises waste.

- Motors and machine drive below working table to ensure operator safety.

- Integrated ergonomic tube loading system, swings aside for easy access.

- Fold and roll crimping system for closing metal; plastic/laminate tubes sealed by hot air.

TGM M100 Filler & Closer

Faster Filling, Higher ROI

Compact & Space-Efficient

Up to 2,400 Containers per Hour

Product Specification:

- Highly efficient filling, stoppering and capping.

- Ideally suited to 1 - 50ml containers.

- Maximum container sizes 50mm diameter, 150mm high.

- Filling accuracy of up to +/-0.5% reduces waste.

- Designed for ease of cleaning and changeover, with GMP in mind.

- “No bottle no fill”, “No cap”, “Badly tightened cap” sensors reduce waste.

- Swift 15-20 minute changeover time reduces costly production downtime.

- Peristaltic, volumetric displacement or vacuum pump options to best suit the product.

- Suitable for screw caps, push on caps, ROPP caps, clinched seals for pump sprays or vials, plugs, pipettes, droppers, stoppers and security caps.

Please Note: This machine can be used in cleanroom environments, with air exhaust modifications.

Drum Decanting Unit

Durable & Robust

Reduces Waste, Increases Profitability

Exceptional Output, 50L per min

Product Specification:

- Maximum product viscosity: 13,000 Cst.

- Maximum product temperature: 100 Celcius.

- Ideal for 200L Drums and 1,000L IBC's.

- Decanting Pump Output: 195L @ 1000 cSt per minute.

- Includes rinsing kettle with weigh scale option from 500 litres to 1,000 litres.

- Levels of precision, repeatability and hygiene that are extremely difficult to match manually.

- Time-efficient cleaning: when the lance exits the drum it enters the rinsing kettle, where it cleans itself inside and out, ready for use on another product.

- When nearing empty, the drum can be tilted to ensure that maximum product removal is achieved, and the drum is then rinsed with hot base oil to minimise product waste.