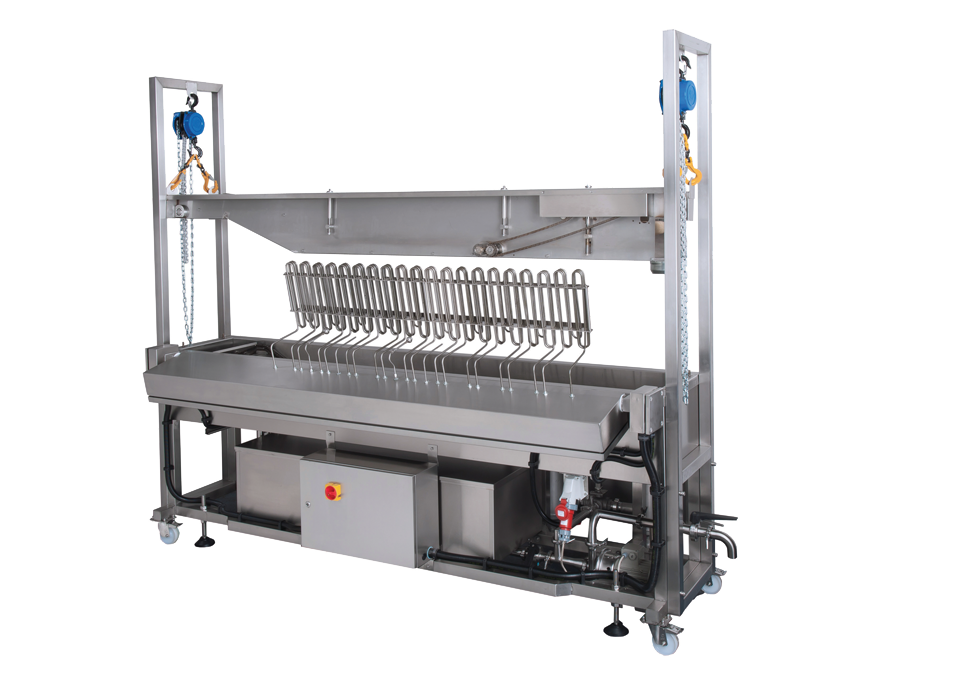

- The EconoFry is the versatile, cost effective frying solution for small, medium and large producers.

- The digitally controlled heating and continuous conveyor system ensures a wide variety of products are fried to a consistently high standard. Having the ability to flash fry or fully cook, the EconoFry is suitable for a vast array of produce from spring rolls, onion bhajis and falafel to fish fingers, burgers and chicken nuggets.

- The EconoFry forms part of the Deighton Manufacturing (UK) Ltd further processing line and is available in widths of 200, 300, 400 & 600mm.

2.IN Details

The EconoFry is an electrically heated fryer with elements immersed directly into the insulated frying tank for the most efficient heat transfer.

This method imparts 97 – 99% of the heat directly into the oil using low density elements so as not to degrade the quality of the cooking medium. The system runs on a three phase supply and is simply operated from a central control panel.

The product passes between the bottom conveyor and adjustable hold down conveyor (supplied as standard), ensuring continuous emersion in the cooking oil at all times, along the length of the fryer. Cooking time and temperature are completely adjustable, enabling the producer to finely adjust the appearance and level of readiness of each individual product.

Complete with oil level detection and automatic low level cut-out system, removable conveyor unit and hinged element enclosures, the EconoFry offers a safe and easy to maintain solution to your frying requirements.

- Technical Specifications

EconoFry 200 x 3m (belt width x length)

Width (A): 2800mm

Length (B): 1100mm

Height (C): 1300mm

Power: 23Kw

Electricity Supply: 380/415V

Tank Capacity: 180L

Output (approx): 200kg/ hr

EconoFry 200 x 5m (belt width x length)

Width (A): 4800mm

Length (B): 1100mm

Height (C): 1530mm

Power: 41Kw

Electricity Supply: 380/415V

Tank Capacity: 350L

Output (approx): 400kg/ hr

- Optional Extras

- Teflon Infeed: Adjustable angle for the frying of battered or delicate products.

Sediment Removal System: A scraper system which removes sediment from the tank bottom.

- Oil Filtration: Continuous filtering system to enhance product finish and lengthen oil life. Hoists: Manual or electric system for the removal of the conveyor unit.

- Storage Tank: A tank situated underneath the fryer for the storage of oil either overnight or when cleaning. Supplied with a pump for refilling of the fryer