- Details

- Category: Coating & Breading Machines

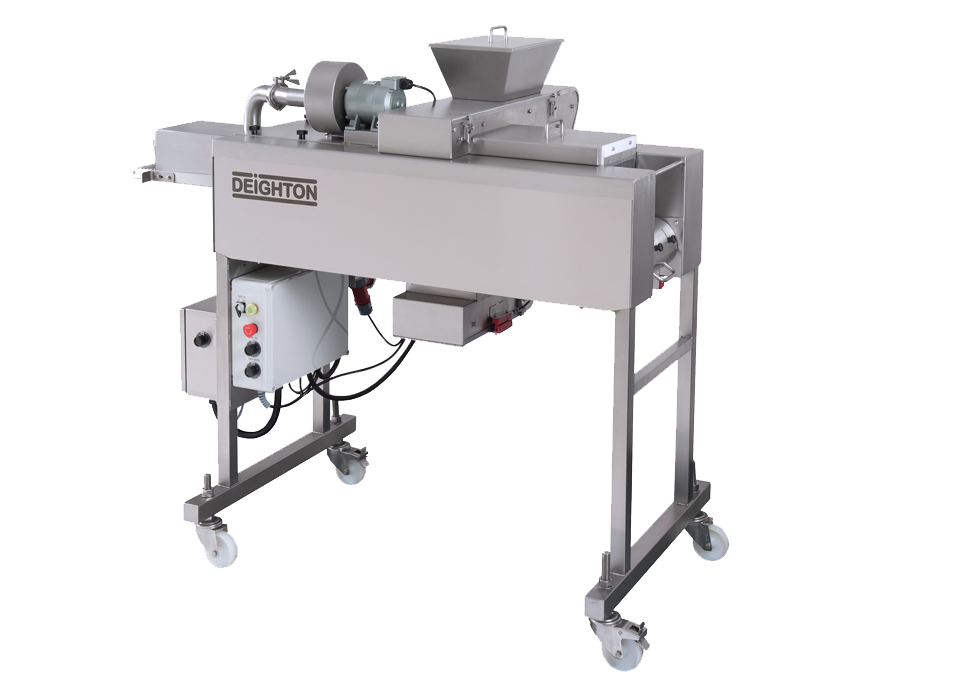

The EconoDust has been developed to make the automated process of pre dusting products accessible to small and large volume producers.

Designed to apply a thin coating of dust or flour to enhance batter adhesion, the EconoDust enables the operator to enjoy maximum versatility with their product range at an affordable cost whilst maintaining its reliability and ease of operation & cleaning.

The EconoDust forms part of the Deighton Manufacturing (UK) Ltd further processing line and is available in widths of 200, 300, 400 & 600mm.

Operating from a three phase supply, the EconoDust can be installed as a stand alone unit or as a part of the forming and processing line. A single control panel operates the variable speed conveyor that transfers the product through the unit.

The conveyor is submerged in a bed of dust ensuring that, as the product passes along the conveyor, a full & even coating is applied to the underside of the product. The conveyor moves the product through the dust “curtain” showering a consistently accurate coating to the remaining areas by means of an adjustable speed trans-flow conveyor.

The fully dusted produce proceeds to pass underneath a variable pressure air knife which removes any excess dust before presenting it for the next processing or packaging stage.

The excess dust is recycled back into the tank and trans-flow conveyor, allowing the operator to minimize product wastage

- EconoPredust 200

Width (A): 1000mm

Length (B): 1600mm

Height (C): 1430mm

Weight: 140kg

Power: 1180w

Electricity Supply: 380/415v

Tank Capacity: 25Ltr

Output (approx): 350kg/hr

- EconoPredust 300

Width (A): 1100mm

Length (B): 1600mm

Height (C): 1430mm

Weight: 170kg

Power: 1180w

Electricity Supply: 380/415v

Tank Capacity: 37Ltr

Output (approx): 450kg/hr

- EconoPredust 400

Width (A): 1200mm

Length (B): 1600mm

Height (C): 1430mm

Weight: 200kg

Power: 2120w

Electricity Supply: 380/415v

Tank Capacity: 50Ltr

Output (approx): 600kg/hr

- EconoPredust 600

Width (A): 1400mm

Length (B): 1600mm

Height (C): 1430mm

Weight: 250kg

Power: 2120w

Electricity Supply: 380/415v

Tank Capacity: 75Ltr

Output (approx): 900kg/hr

- Details

- Category: Coating & Breading Machines

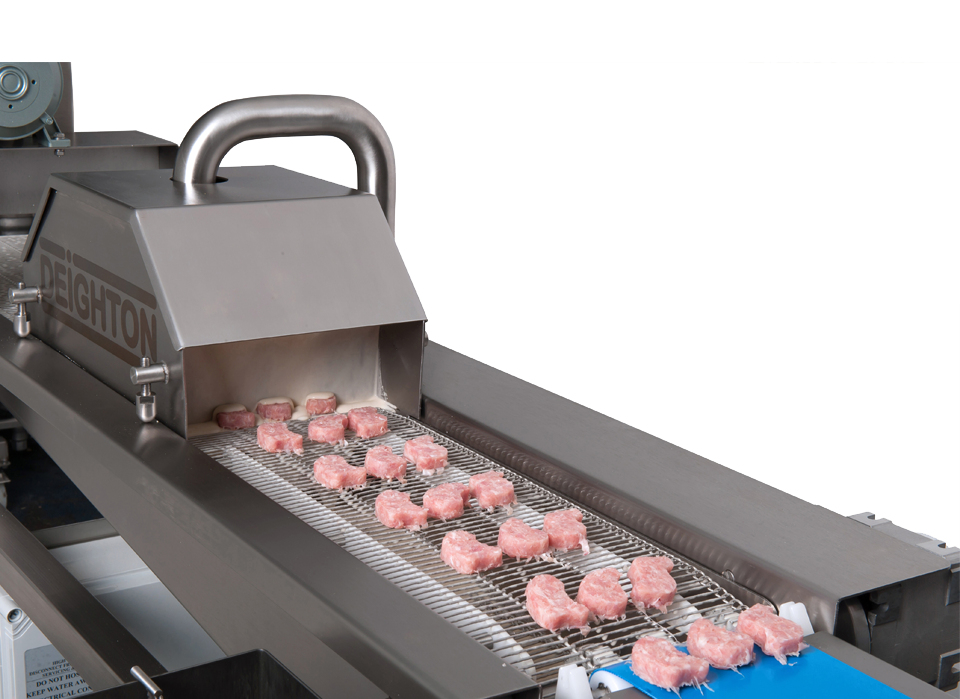

The EconoRobe applies high quality coverage of numerous batters and marinades and is successful with a host of meat, fish, ethnic and vegetable produce.

Available in either “weir” or “dip” style the system can effectively handle adhesive or tempura mixes and the ease of switching batters between production runs allows the producer the freedom to maximize production efficiency.

The EconoRobe forms part of the Deighton Manufacturing (UK) Ltd further processing line and is available in widths of 200, 300, 400 & 600mm.

Weir Enrober The weir style Enrober can be used for all adhesive batters and marinades of varying viscosities.

The system consists of a variable speed conveyor which passes through a “puddle plate” and “water fall” of the required batter to totally cover the product. This batter is recirculated from the batter tank, through a filter basket and back up to the waterfall by a centrifugal pump situated underneath the batter tank. Any excess batter on the product is removed by a variable pressure air knife before presenting for the next process or packaging stage.

Dip Enrober The dip style Enrober is suitable for tempura and high viscosity batter where mixing through a pump is not preferable.

The system consists of a variable speed conveyor which passes product through the system. As the product travels along the conveyor it is fully submerged into a tank of batter. A weighted top conveyor assists to channel the product through the tank, ensuring that the product remains completely immersed in the batter or chosen marinade at all times. As the product leaves the tank a variable pressure air knife removes any excess batter before presenting for the next process or packaging stage.

EconoRobe 200

- Width (A): 580mm

- Length (B): 1400mm

- Height (C): 1360mm

- Weight: 100kg

- Power: 950w

- Electricity Supply: 380/415v

- Tank Capacity: 12Ltr

- Output (approx): 350kg/ hr