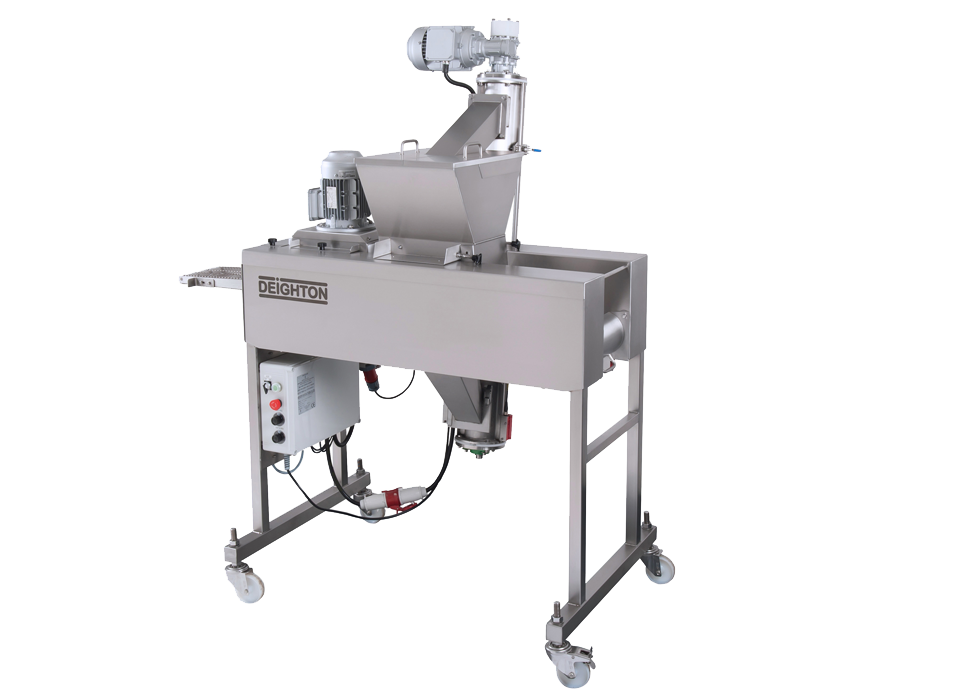

- The EconoCrumb has been developed to make the automated process of crumbing formed or batter coated product accessible to small and large volume producers.

- Designed to handle numerous types of crumb, the EconoCrumb enables the operator to enjoy maximum versatility with their product range at an affordable cost whilst maintaining its reliability and ease of operation & cleaning.

- The EconoCrumb forms part of the Deighton Manufacturing (UK) Ltd further processing line and is available in widths of 200, 300, 400 & 600mm.

- Operating from a three phase supply, the EconoCrumb can be installed as a stand alone unit or as a part of the forming and processing line. A single control panel operates the variable speed conveyor that transfers the product through the unit. The conveyor is submerged in a bed of crumb ensuring that, as the product passes along the conveyor, a full & even coating is applied to the underside of the product. The conveyor moves the product through the crumb “curtain” showering a consistently accurate coating to the remaining areas. The thickness of crumb bed and curtain are fully adjustable to achieve the desired weight of coating.

- The fully coated produce proceeds to pass underneath a compressing roller which gently compacts the crumb around the product, before any excess is removed by the variable pressure air knife.

- The excess crumb is recycled through the auger and transferred back to the hopper, allowing the operator to minimize product wastage.

EconoCrumb 200

Width (A): 960mm

Length (B): 1600mm

Height (C): 1850mm

Weight: 170kg

Power: 1750w

Electricity Supply: 380/415v

Tank Capacity: 30Ltr

Output (approx): 350kg/hr