- Details

- Category: MOCON

The Dansensor® Can Piercer for gas detection is used for accurate headspace sampling of cans, containers, and bottles. This product is an ideal can piercer for the beverage industry.

- Milk Powder cans

- Wine bottles

- Soft drink cans

- Ready to drink containers

- PET bottles

Overview

The Dansensor® Can Piercer is an efficient headspace sampling tool for canned products. It should be used in conjunction with either Dansensor® CheckMate 3 or Dansensor® CheckPoint 3 to determine headspace gas concentration levels in these packages. Compatible headspace analyzers and software are described below.

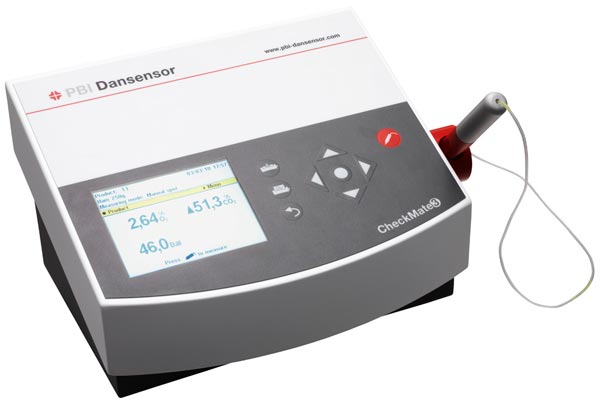

- Dansensor® CheckMate 3

Dansensor CheckMate 3 makes quality control easier to maintain due to its ability to measure O2 and combined O2 and CO2 gas mixtures in Modified Atmosphere Packaging products of all shapes and sizes. - Dansensor® CheckPoint® 3

Dansensor CheckPoint 3 is the most advanced portable gas analyzer available. This highly regarded headspace measurement tool applies a long-lasting sensor which delivers highly accurate measurements of O2 and CO2 in Modified Atmosphere Packaging products. - Dansensor® CheckMate PC Software

In large MAP production environments, it can be difficult for Quality Control managers to keep track of every headspace analyzer, but with Dansensor CheckMate PC software, it is possible to control several CheckMate headspace measurement tools at the same time, thereby facilitating an easier way of evaluating data about headspace gas.

Accessories

Pressure relief kit

Applications

The Can Piercer is an option for our headspace analyzers. The Can Piercer is typically used for measuring headspace in the following packaging types:

- Milk powder cans

- Soft drink cans

- Wine bottles

- Ready to drink containers

- PET bottles

- Details

- Category: MOCON

Ensure a consistently good Modified Atmosphere Packaging quality with headspace analysis.

- Options for both O2 and CO2/O2 analysis

- Automatic data logging

- Easy operation with a 5” color display touchscreen

- Simple data transfer with CheckMate PC Software

- Small sample volume requirements from 3 ml

Overview

Headspace gas analysis is an important part of quality control for MAP products. Accurately measuring the headspace gas levels contributes to ensure a repeatedly high Modified Atmosphere Packaging quality and with Dansensor® CheckMate 3, our benchtop analyzer for O2 and CO2, operators can tell at a glance whether the gas composition meets the required levels.

Headspace analyzers:

Using the Dansensor CheckMate 3 is only one option for conducting Modified Atmosphere Packaging analysis of headspace gas compositions. We offer a range of other products for measuring headspace gas each of which will be introduced here:

- Dansensor® CheckPoint® 3

The Dansensor CheckPoint 3 relies on a revolutionary sensor technology which makes it the most advanced and accurate portable gas analyzer available. It checks for both O2 and CO2 levels in MAP products. - Dansensor® CheckMate PC Software

Transfer and analysis of package data is much easier using the Dansensor CheckMate PC Software which works with both Dansensor CheckMate 3 and Dansensor CheckPoint 3. This is an ideal tool for Quality Control managers working in large production environments since it can control several CheckMate units at the same time. - Dansensor® Can Piercer

The headspace gas of cans and bottles can be analyzed accurately using the Dansensor Can Piercer. The Dansensor Can Piercer tool should be used with either Dansensor CheckPoint 3 or Dansensor CheckMate 3. - Dansensor® OpTech

Modified Atmosphere Packaging quality can be improved significantly using the innovative Dansensor OpTech for headspace analysis. The analyzer is based on the non-invasive measurement method which sets it apart from competing products.

Features & Benefits

Benefits

- Saves labor time and paperwork due to automatic data logging

- Easy transfer of quality control data to the Dansensor CheckMate PC software or third party software Measuring range: 1 ppm - 100% (std. 0-20.9%)

- Reliable quality control of gas flushed products

- Easy operation – a minimum of training required

Features

- Large easy to read 5” color display with touch function

- Available for either oxygen (O2) or combined oxygen/carbon dioxide (O2/CO2) measurement

- Very small sample volume requirement (from 3 ml)

- Data transfer via Ethernet/(LAN), USB or RS232

- Flexible configuration of test scheme, e.g. logging of operator name, batch number, product line, etc.

- USB connection for external keyboard and bar code scanner

- Optional built-in printer

Technical Specifications

|

Available configurations |

O2 (Zirconia) |

O2 (Electrochemical) |

CO2 (Infrared dual beam sensor) |

|

Key features |

Our fastest and most accurate oxygen sensor |

Not cross-sensitive to alcohol, carbon monoxide or carbon dioxide. (Electrochemical sensors are consumable sensors) |

Full-scale temperature compensated carbon dioxide sensor (Electrochemical sensors are consumable sensors) |

|

Sample volume (minimum) |

3 ml |

5 ml |

5 ml |

|

Sample time (minimum) |

5 sec |

7 sec |

10 sec |

|

Measuring range |

0-100% |

0-100% |

0-100% |

|

Resolution |

0.001% |

0.1% |

0.1% |

|

Accuracy |

± 0.01% |

± 0.1% |

± 0.8% |

|

Heating time |

10 min |

N/A |

10 min |

|

Dimensions & weight |

180 x 315 x 220 mm (HxWx D), 3.7 kg |

||

|

Power supply |

100-240 VAC, 50-60 Hz |

||

|

Options |

Built-in printer, CheckMate PC software, SmartPen – retractable syringe, Can Piercer for testing cans and wine bottles, bar code scanner, standard consumable kit ( part no. 300436 ) |

||

|

Connections |

USB, Ethernet (RJ45), RS232 (DB9) |

||

|

Memory |

1,000 programs (products) and minimum 10,000 measurements, depending on the setup |

||

|

Third-party software compatibility |

Mettler-Toledo FreeWeigh.net, Sartorius ProContol (WinSPC), OCS ComScale NT, Microsoft SQL database Bizerba _statistics.BRAIN |

||

|

Compliances |

|||

Accessories

Consumable

- Needle kits

- Septums

- Sample kits

- Filters

- Hoses for sample gas

Accessories

- SmartPen

- PC software

- Cables for PC connection

- Sampling kit

- Barcode scanner

- IQ/OQ documents

Service & Support Options

- Basic Preventative Maintenance Plan

- Plus Preventative Maintenance Plan

Applications

Table top Head space analyzer measuring the gas content in MAP packages

- O2 measurements

- O2 + CO2 measurements

For a variety of food, beverage, pharmaceutical and medical packages using MAP.

Some examples of our customer applications include:

Snack Foods - Bakery - Pizza - Meats & Cheese - Nuts - Fish - Fruit, salads & Vegetables - Pet Foods - Pharmaceutical Packaging - Medical Device

- Details

- Category: MOCON

Looking for a gas analyzer that’s state-of-the-art – yet simple enough for everyone to work with? Then check out the CheckPoint II. It’s “simply” advanced – easy to use plus packed with everything needed to make the transition from paper-based to electronic record keeping. No more recording of test results twice: simply indicate the batch number and product ID and you’re assured of efficient, error-free transfer of test data to a PC.

CheckPoint II is perfect for small to medium-sized operations – or for situations where you simply want a device you can carry around. Built-in intelligence alerts you to any irregularities with the gas content of your packages.

Benefits of CheckPoint II portable headspace analyzer

- Easy operation – a minimum of training required

- Transfer and analyse quality control data easily

- Can be configured to match any quality control setup

- Robust design – will withstand many years of operation

- Ergonomic design - safe to use for the operator

- Easy set-up via included PC software

- Ready to use, right from the box

Features of CheckPoint II O2/CO2 headspace analyzer

- Available for either oxygen (O2) or combined oxygen/carbon dioxide (O2/CO2) measurement

- PC software included

- Easy data transfer to a PC via the included DockIn

- Standard, low-cost syringes

- Optional built-in bar code scanner for product, operator and batch selection

- Oxygen sensor is immune to CO2

- Details

- Category: MOCON

Portable Gas Analyzer for quality control of modified atmosphere packages (MAP).

- Different sensor variants ensure compatibility with all applications

- O2 or combined O2/CO2 measurements

- Data collection/transfer via WiFi

Overview

Our best-selling Dansensor® CheckPoint® 3 is now available with an electrochemical sensor. The electrochemical sensor is designed for food applications including applications with a high concentration of oxygen in the headspace.

Food applications the Dansensor CheckPoint 3 EC is designed for:

- Bread (treated with alcohol)

- Coffee

- Fermented products

- Fish (smoked)

- Fresh pasta

- Red and smoked meat

With Dansensor® CheckPoint 3 CO2 and O2 levels can quickly be checked for Modified Atmosphere Packages in all shapes and sizes. The handheld gas analyzer is easy to use, fast at processing data, and uses an optical sensor to provide the highest level of accuracy among similar products. This is an efficient way of improving MAP quality control.

Users of Dansensor CheckPoint 3 furthermore enjoy features and benefits, including:

- Improved process efficiency

- Low cost of ownership

Headspace analyzers:

This portable gas analyzer is part of a family of headspace analyzers. Below is a brief introduction to other related products in the category, explaining their features and how they differ from and complement the Dansensor CheckPoint 3 handheld gas analyzer.

- Dansensor® CheckMate 3

Like the Dansensor CheckPoint 3, the Dansensor CheckMate 3 is a cost-effective headspace analyzer that allows for operators to measure both O2 and gas mixtures combining O2 and CO2. It is a benchtop analyzer, versus the portable CheckPoint 3. - Dansensor® CheckMate PC Software

This software can control several Dansensor headspace analyzers in large MAP production environments. This makes it easier to collect and evaluate data about the headspace gas of products tested with either Dansensor CheckMate ll or CheckMate 3. - Dansensor® Can Piercer

The correct mixture and amount of headspace gas is vital to the quality of canned products. To ensure compliance with requirements and to achieve consistency in the delivery of prolonged shelf-life products, the Dansensor Can Piercer can be used to sample the headspace gas of milk powder cans, wine bottles and similar containers. Use it in conjunction with a CheckPoint or CheckMate Analyzer to get accurate headspace gas analysis for your canned goods. - Dansensor® OpTech

Dansensor OpTech is made for measuring the oxygen levels in MAP products. It is most often used in laboratories and is recognized for its ability to conduct non-invasive oxygen measurements through transparent foil.

Features & Benefits

Benefits

- No PC software required

- Easy to use

- Improves MAP quality control

- Better process efficiency

- Greater business transparency

- Secures your brand’s reputation

- Highest level of portable analyzer

- Low cost of ownership

- No daily 20.9% calibration

Features

- Different sensor variants ensure compatibility with all applications

- O2 or combined O2/CO2 measurements

- Gas flow alarm

- Fast processing and graphic statistics

- Easy-to-read 3.5” color touchscreen

- Uses standard, low-cost needles

- Multiple languages

- PREMIUM version features includes::

- Create up to 10 user accounts on the device

- Add up to 100 product profiles to streamline and regulate data

- Automatic logging to remove the risk of human error

- Data collection/transfer via WiFi

Technical Specifications

|

Available configurations |

O2 (ceramic solid state sensor) |

O2 (electrochemical sensor) |

CO2 (infrared single beam sensor) |

|

Sample volume (minimum) |

5 ml |

5 ml |

5 ml |

|

Sample time (minimum) |

7 sec |

7 sec |

7 sec |

|

Measuring range |

0-55% |

0-100% |

0-100% |

|

Resolution |

0.1% oxygen |

0.1% oxygen |

0.1% carbon dioxide |

|

Sensor accuracy |

±(0.1% O₂ + 2% of readout) |

±(0.25% O₂ + 2% of readout) |

±2% CO₂ in range 0-20% |

|

Heating time |

5 sec |

N/A |

N/A |

| Expected sensor lifetime | > 3 years | > 1 year (depending on use) |

> 5 years |

| Food applications | Vegetables (raw and prepared), meat (processed), fish (raw and prepared), cheese, prepared meals, snack foods, beverage |

Meat (raw and smoked), fish (smoked), bread (treated with alcohol), fresh pasta, fermented foods, coffee | All |

|

Dimensions & weight |

75 x 100 x 175 mm (HxWxD), 0.7 kg |

||

|

Power supply |

Battery powered; up to 2000 measurements on a fully charged battery at 20 °C; recharge time maximum 5 hours |

||

|

Options |

Standard consumable kit (1 sampling kit, 1000 septums, 10 needles (Ø 0.8) & 10 water trap filters), metal needles |

||

|

Connections |

WiFi (WPA, WPA 2, WPA enterprise) |

||

|

Calibration and service |

12 months |

||

|

Working temperature |

0 to +40°C, less than 95% RH, non condensing |

||

|

Compatibility |

RoHS, China RoHS, CE |

||

|

Data package |

Extended memory - up to 1 million measurements |

||

|

What's included in the box? |

100 septums, 10 needles (Ø 0.8), 10 water trap filters, power supply w/interchangeable plugs (US, EU, AU, UK) |

||

Accessories

Consumable

- Needle kits

- Septums

- Sampling kits

- Filters

- Hoses for sample gas

Accessories

- Protective side covers

- IQ/OQ documents

Service & Support Options

- Basic Preventative Maintenance Plan

- Plus Preventative Maintenance Plan

Applications

Portable Head space analyzer measuring the gas content in MAP packages

- O2 measurements

- O2 + CO2 measurements

For a variety of food, beverage, pharmaceutical and medical packages using MAP.

Some examples of our customer applications include:

Snack Foods - Bakery - Pizza - Meats & Cheese - Fish - Fruit, salads & Vegetables - Pet Foods - Pharmaceutical Packaging - Medical Device

- Details

- Category: MOCON

Checkpoint Hand Held Gas Analyzer

Measuring oxygen and carbon dioxide content is a must, whether your packages are few or many. The only real question is: Which testing device suits your operations best? For smaller production runs, or if you’re just getting started with gas flushing, we recommend the CheckPoint portable analyzer.

CheckPoint gives you all the answers you’ll need—and in seconds. There’s nothing complicated about it: no need to adjust the flow, no need to compensate for temperature, no worries about cross-sensitivity or other technical issues. Simply power it up and start testing. Dansensor’s proven sensor technology ensures accurate and reliable measurements every time.

Benefits of CheckPoint handheld gas analyzer

- Easy operation – no training required

- Robust design – will withstand many years of operation

- Ergonomic design - safe to use for the operator

Features of CheckPoint handhled gas analyzer

- Available for either oxygen (O2) or combined oxygen/carbon dioxide (O2/CO2) measurement

- Stores the last 9 measurements

- Battery powered, up to 2,000 measurements

- Standard, low-cost syringes

- Easy two-button automatic offset calibration

- Oxygen sensor is immune to CO2.