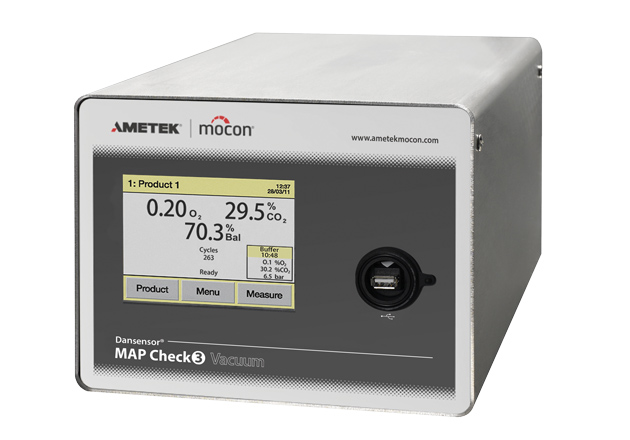

On-line gas analyzer for quality assurance of thermoforming and tray sealing machines.

- Oxygen or combined oxygen and carbon dioxide measurement

- Continuous monitoring and effective control of every packaging cycle

- Automatic production halt in case of exceeded gas limits to avoid recalls or repackaging

- User configurable alarms for low and high gas concentrations

Overview

The Dansensor® MAP Check 3 Vacuum gas analyzer provides on-line quality assurance of thermoforming and tray sealing lines by measuring gas composition on a continuous basis. This ensures an effective MAP process line without compromising on quality. This vacuum gas analyzer for Modified Atmosphere Packaging automatically alerts operators and halts the production process if preset gas limits are exceeded. Logging with USB and Ethernet and with PC software for LAN based data collection.

On-line gas analyzers:

The Dansensor MAP Check 3 Vacuum on-line gas analyzer for quality assurance of MAP tray sealing and thermoforming machines is one product in a line of several on-line gas analyzers for MAP processes we offer. The other gas analyzers in the product family are briefly introduced below.

- Dansensor® MAP Check 3

Avoid gas waste with automated on-line Quality Assurance of every package for both horizontal and vertical Modified Atmosphere Packaging flow wrappers. The reliable and highly efficient Dansensor MAP Check 3 will typically reduce gas consumption by 20-50%. - Dansensor® MAP Check 3 Pressure

Dansensor MAP Check 3 Pressure provides a simple and efficient solution to gas analysis from any pressurized source. This gas analyzer secures the right blend of gas and tests for impurities in both oxygen and carbon dioxide. - Dansensor® ISM-3

With the Dansensor ISM-3 oxygen monitor operators are automatically alerted, and oxygen levels adjusted, if they exceed preset limits. The Dansensor ISM-3 for O2 monitoring offers great accuracy and reliability and is digitally controlled with minimal maintenance requirements.

Features & Benefits

Benefits:

- Stops the packaging machine if preset gas limits are exceeded

- Measures every packaging cycle

- Continuous process monitoring of gas content

- Reduces labor and waste costs compared to manual testing

- Avoids recalls/repacking by stopping packaging machine if measurements exceed preset limits

Features:

- Oxygen or combined oxygen and carbon dioxide measurement

- Alarms for low or high gas concentrations

- Improved data logging capabilities with USB and Ethernet

- Ability to control the Dansensor MAP Mix Provectus gas mixer

- Delivered with PC software for LAN based data collection

- Optional measurement of buffer tank gas composition and pressure

- User configurable alarms

- Extended remote monitoring and control options with Modbus TCP

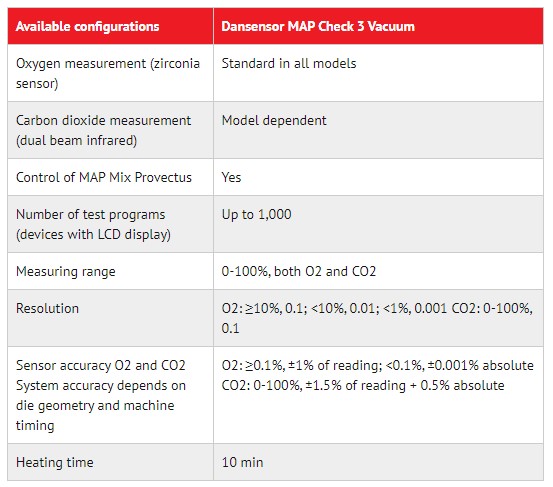

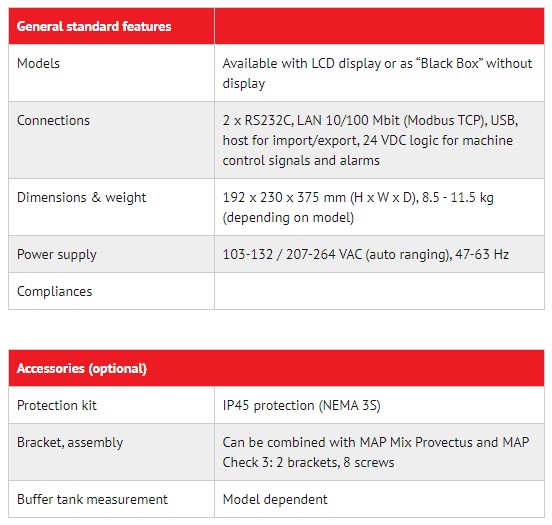

Technical Specifications

Accessories

Consumable

- Filters

- Sampling kits

- Hoses

Accessories

- PC software for MAP Check 3

- Cables for PC connection

- Assembly kit for MAP Check 3 / MAP Mix Provectus

- IP 45 tightening kit

- Non-Return valve

Service & Support Options

- Basic Preventative Maintenance Plan

- Plus Preventative Maintenance Plan

Applications

Applications:

- On-line monitoring of gas content on a Tray or Thermoforming packaging machine

- Above combined with real-time control of package flushing via an advanced GasSave function

For a variety of food and beverage packages using MAP.

Some examples of our customer applications include:

-Prepared meat - Snack Foods - Bakery - Pizza - Meats & Cheese - Fish - Salads & Vegetables - Pharmaceutical Packaging - Medical Device