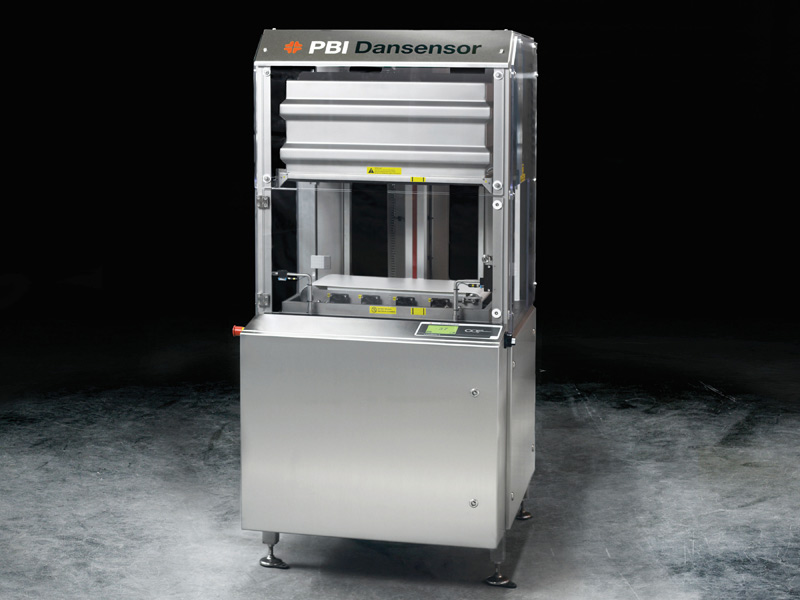

LeakMatic II Packaging Leak Tester

Fully automated non-destructive leak detector - seal integrity of all your modified atmosphere packages is ensured

Now with optical sensor

When the correct management focus is put on seal integrity the benefits can easily be seen in cost reductions. A well-established quality assurance will give reduced waste, reduced product returns, reduced labour and reduced loss of machine time. Hence giving an attractive return on investment time.

Dansensor has developed a compact in-line leak system, which gives the possibility of detecting leaky packages in complete shipping cartons. By using the CO2 already available in the MAP packages as trace gas, it is possible to test all packages shortly after they have left the packaging machine.

This test method is of course non-destructive and furthermore it is possible to test 4-6 shipping cartons per minute.

Overview

The Dansensor LeakMatic II packaging leak tester will reduce both the amount of waste and number of products that are being returned. This is a cost-effective solution which contributes to maintaining a good relationship with retailers.

Features of Dansensor LeakMatic ll packaging leak tester:

- Optical gas sensor

- No heating time

- Data logging of measurement data

- Fully automated non-destructive testing

- Easy operation via touch screen

- 3-year CO2 sensor warranty

Leak detectors:

Besides the Dansensor LeakMatic ll packaging leak tester, we offer two additional leak detectors for quality control of the Modified Atmosphere Packaging process. The whole product family breaks with the traditional (and very cumbersome) ways of conducting leak test and each of the models ensure that seal integrity problems are quickly and accurately identified in order to avoid unwanted returns from retailers and consumers.

- Dansensor® LeakPointer® 3 and LeakPointer® 3+

Dansensor LeakPointer 3 and LeakPointer 3+ detect leak sizes down to 50 microns (µm) to avoid delivering food to retailers that does not meet the requirements for Modified Atmosphere Packaging products within the industry. - Dansensor® LeakPointer® H2O

Dansensor LeakPointer H2O is a premium water bath for visual leak testing (bubble test) on almost all types of packaging. The leak detector is used for quality control checks, R&D package testing and process optimization on the packaging line. - Dansensor® Lippke 5000

Dansensor Lippke 5000 provides reliable seal strength and pressure leak testing of many types of packaging. It can be used production, laboratory environments and throughout the supply chain to test package integrity.

Features & Benefits

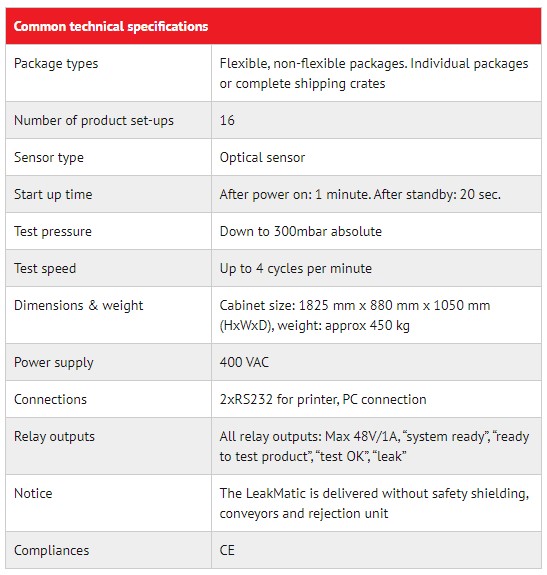

Technical Specifications

Accessories

Consumable

- Filters

- Gasket for chamber

- Oil for vacuum pump

Accessories

- Pack Fix for various packages sizes

- Checkbox

- Delta-P meter

- Leak Simulation kit

Service & Support Options

- Basic Preventative Maintenance Plan

- Plus Preventative Maintenance Plan

Applications

- Non-destructive In-line detection of leaky MAP packages in complete shipping cartons.

- Non-destructive Off-line or sample testing for leaky MAP packages in complete shipping cartons.

For a variety of food packages using MAP.

Some examples of our customer applications include:

Snack Foods - Bakery - Pizza - Meats & Cheese - Fish - Fruit, salads & Vegetables - Pet Foods