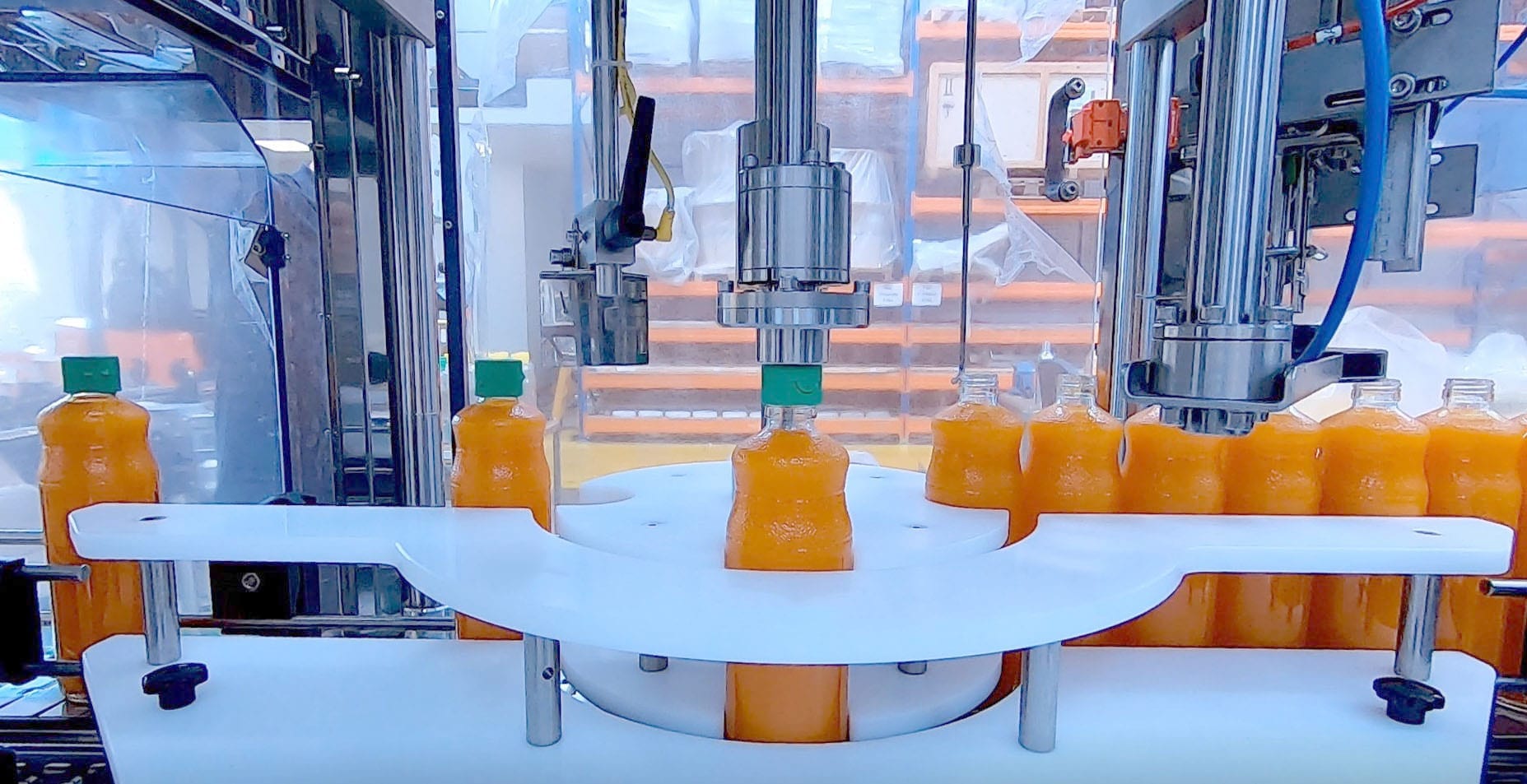

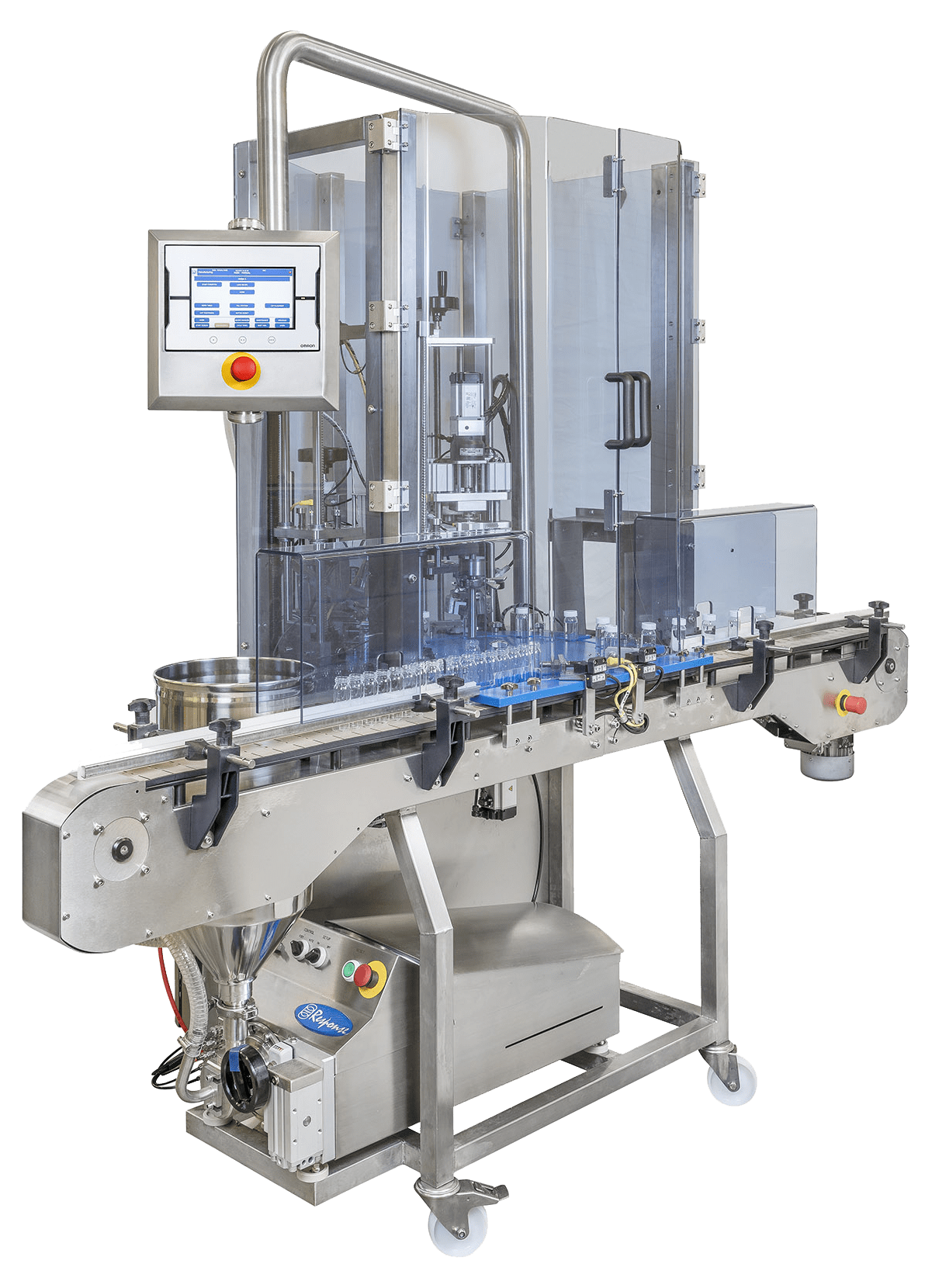

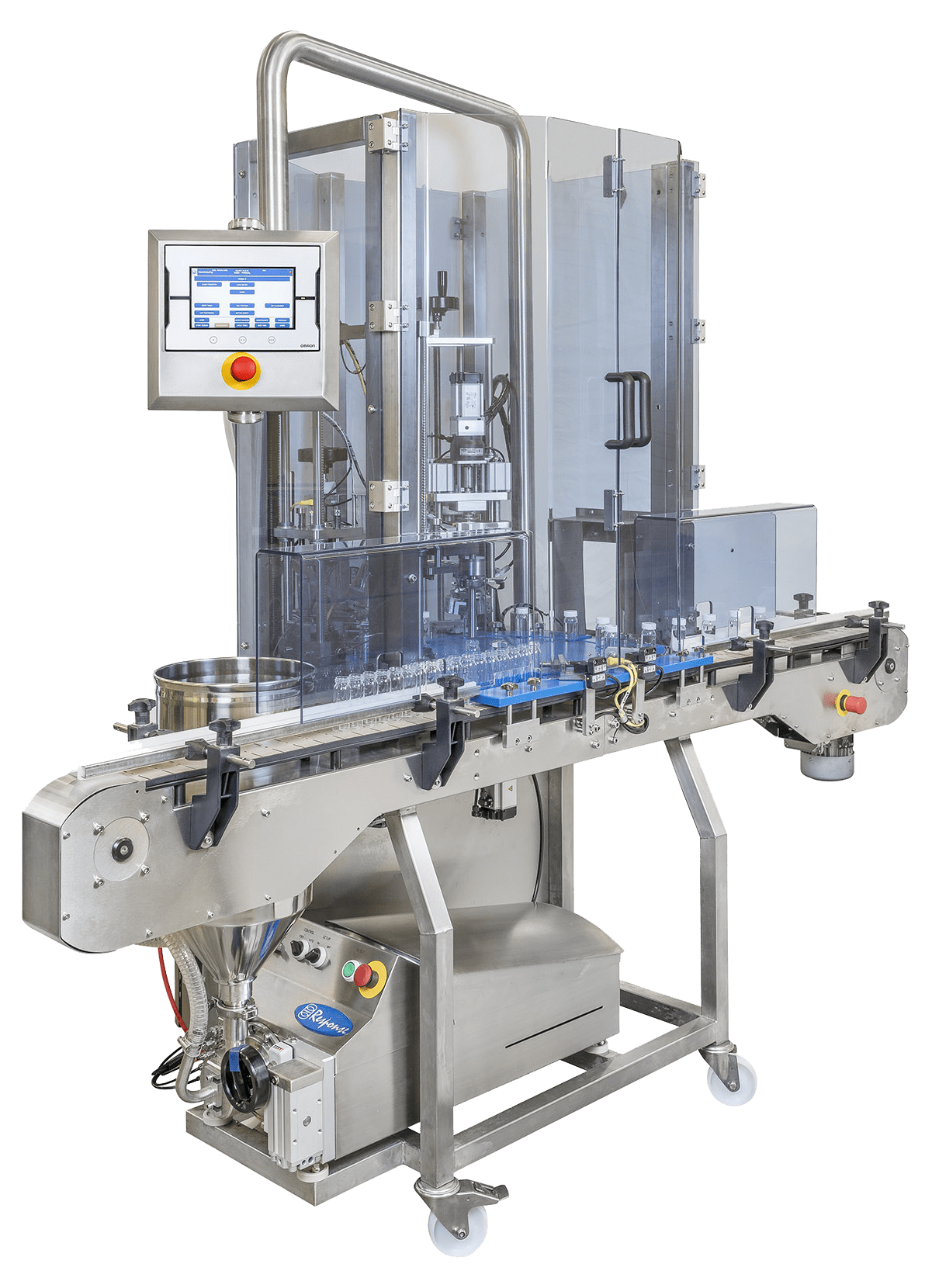

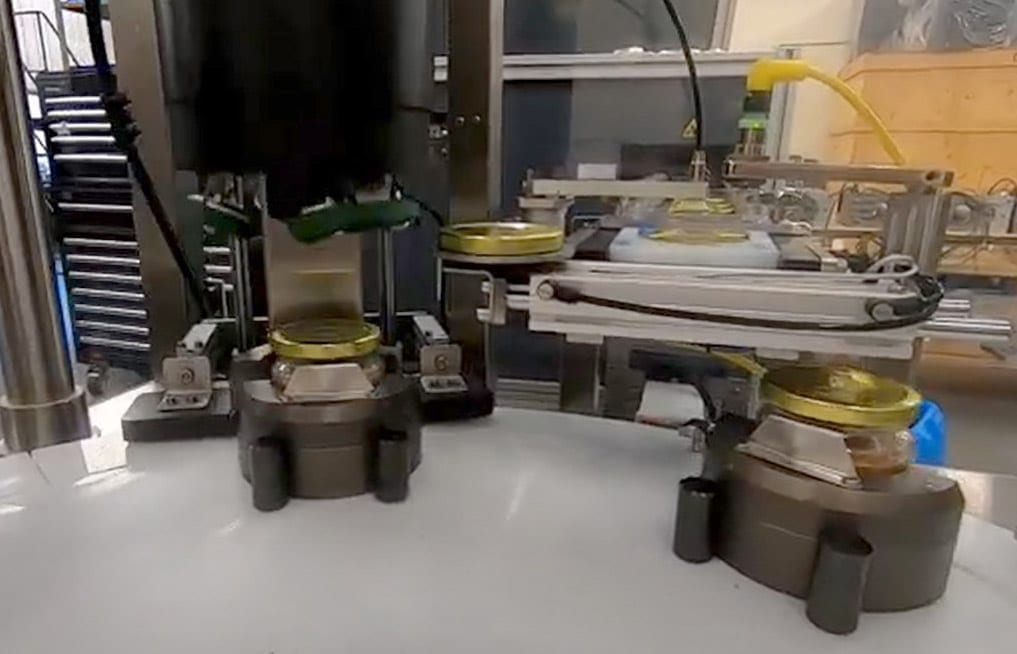

Mastercap Indexing Cappe

High Efficiency & Throughput

Reduces Waste, Increases Profitability

Up to 3,600 Caps per Hour

Product Specification:

- Ideal for cap diameters 20 - 80mm.

- Fast and reliable application of up to 60 caps per minute.

- Robust 304 stainless steel construction.

- Cap track low level detection avoids disrupting production.

- No container, no cap and queue sensing reduces cap waste.

- Easily adjustable variable torque by magnetic clutch.

- Capping zone protected by interlocked guards for operator safety.

- Includes cap feed elevator with pneumatic orientator.

- Can be ATEX compliant for flammable products.

- Suitable for:

- Screw caps

- Press on caps

- Tamper proof caps

- Aerosol overcaps

- Inserts

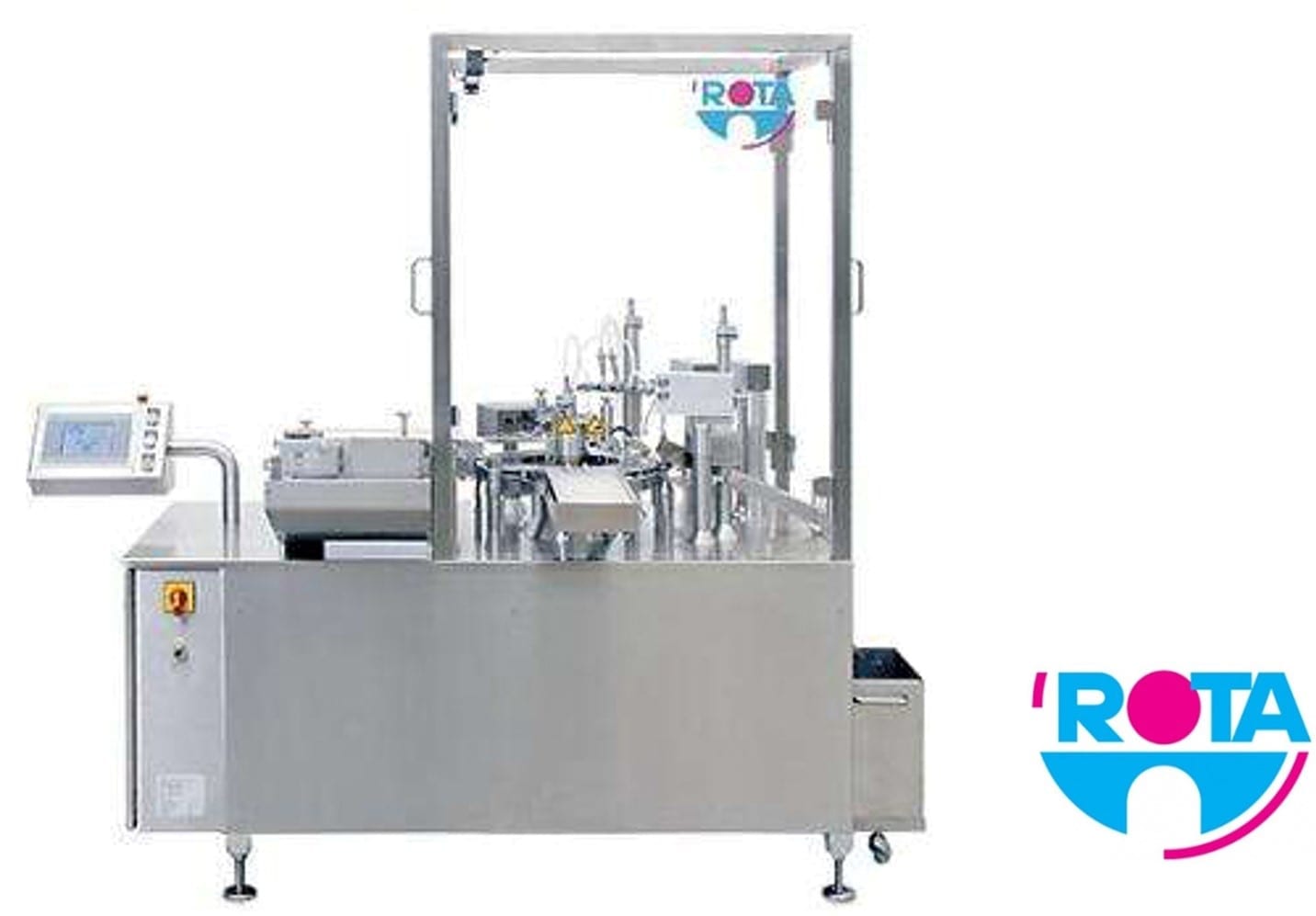

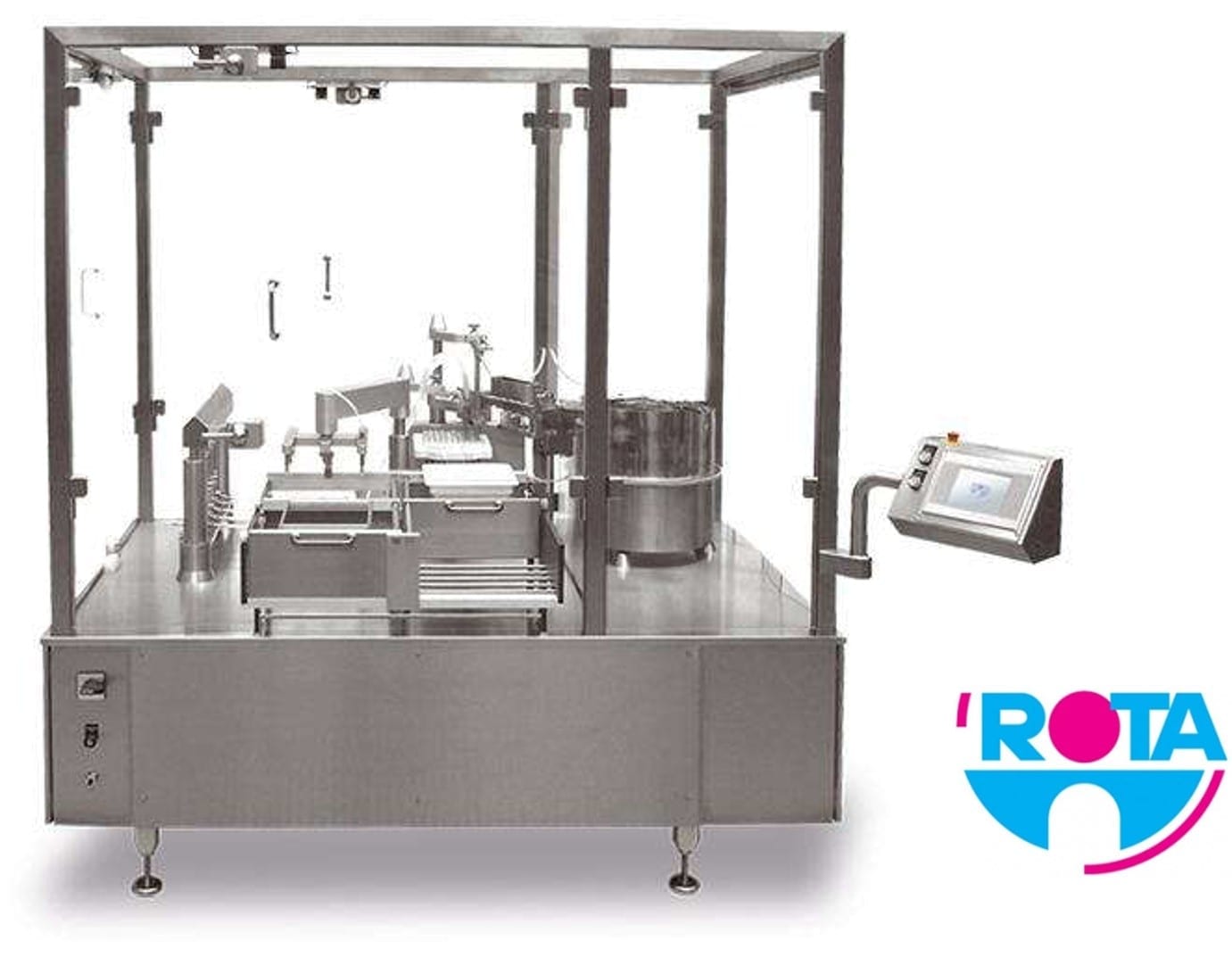

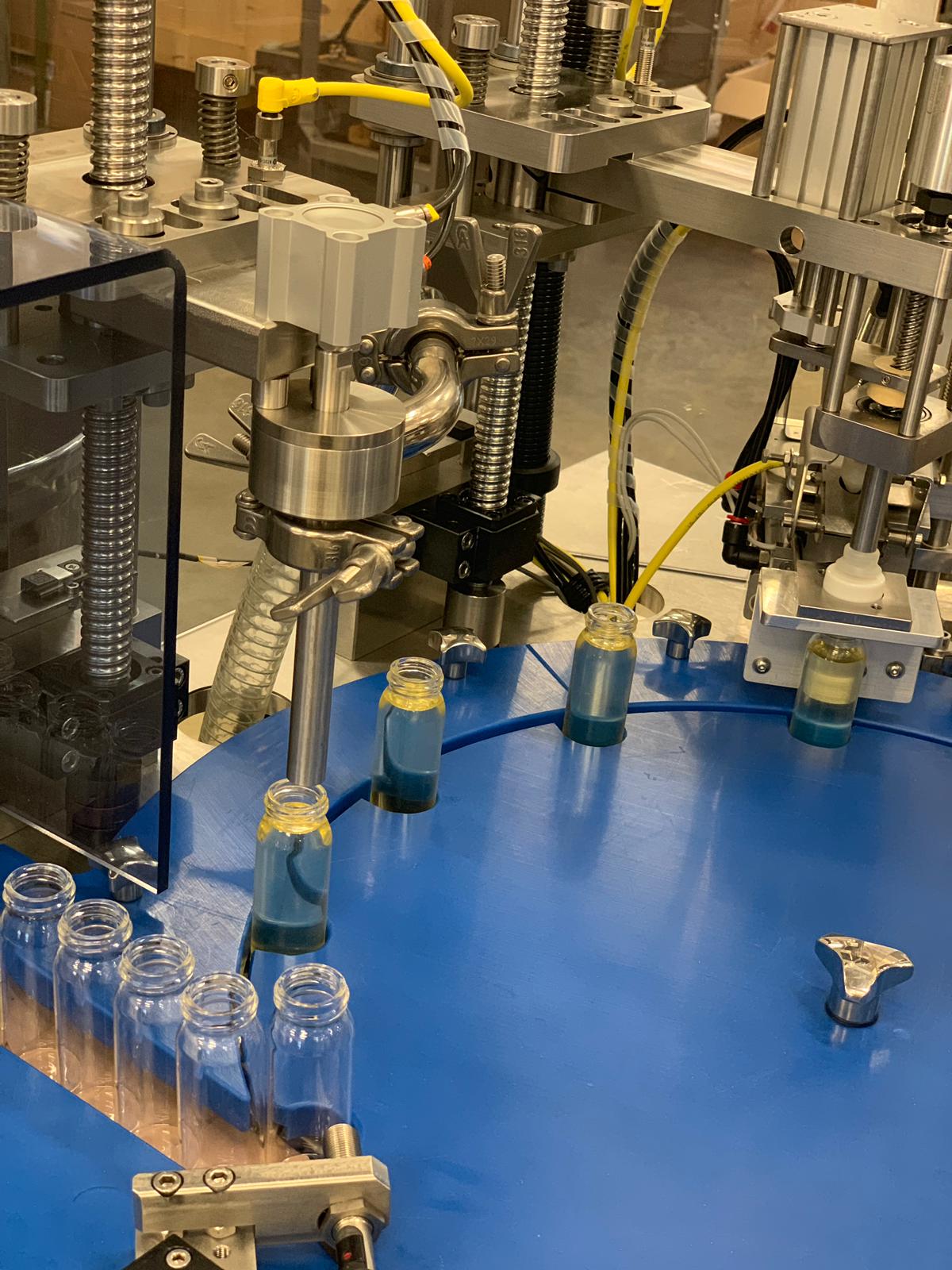

Response Monobloc 250 Filler & Capper

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Make the Most of Your Space

Product Specification:

- Fast filling and capping, up to 35 containers per minute.

- Fill volumes from 3ml to 250ml.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Compact, space-efficient footprint.

- Fills bottles, jars and screw-top vials.

- Easy-to-use intuitive HMI touch screen controls for your operator.

- Quick and easy to change parts from one fill-size container to another.

- Incorporates the Response Benchtop Filler, which can also be independently used if required.

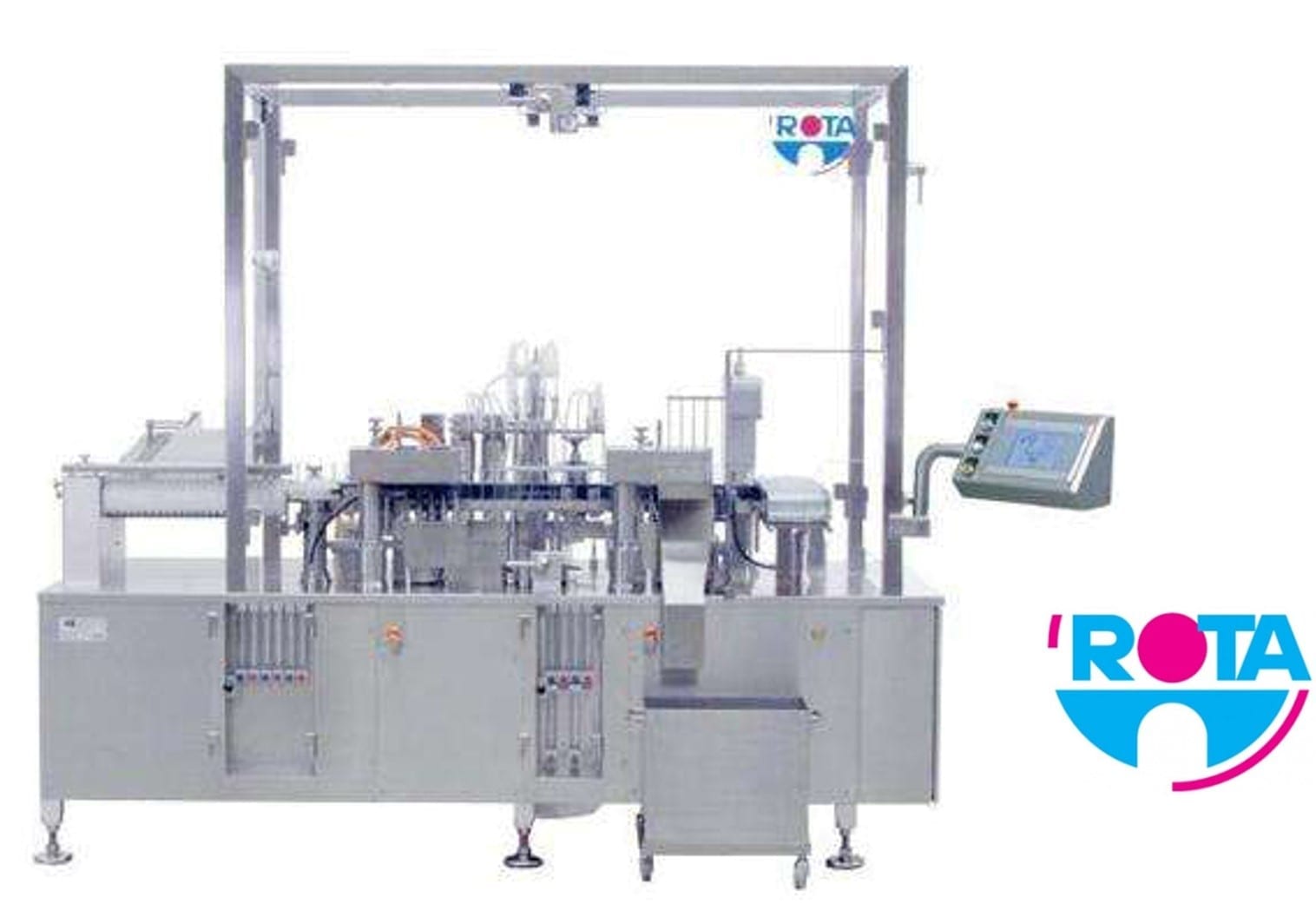

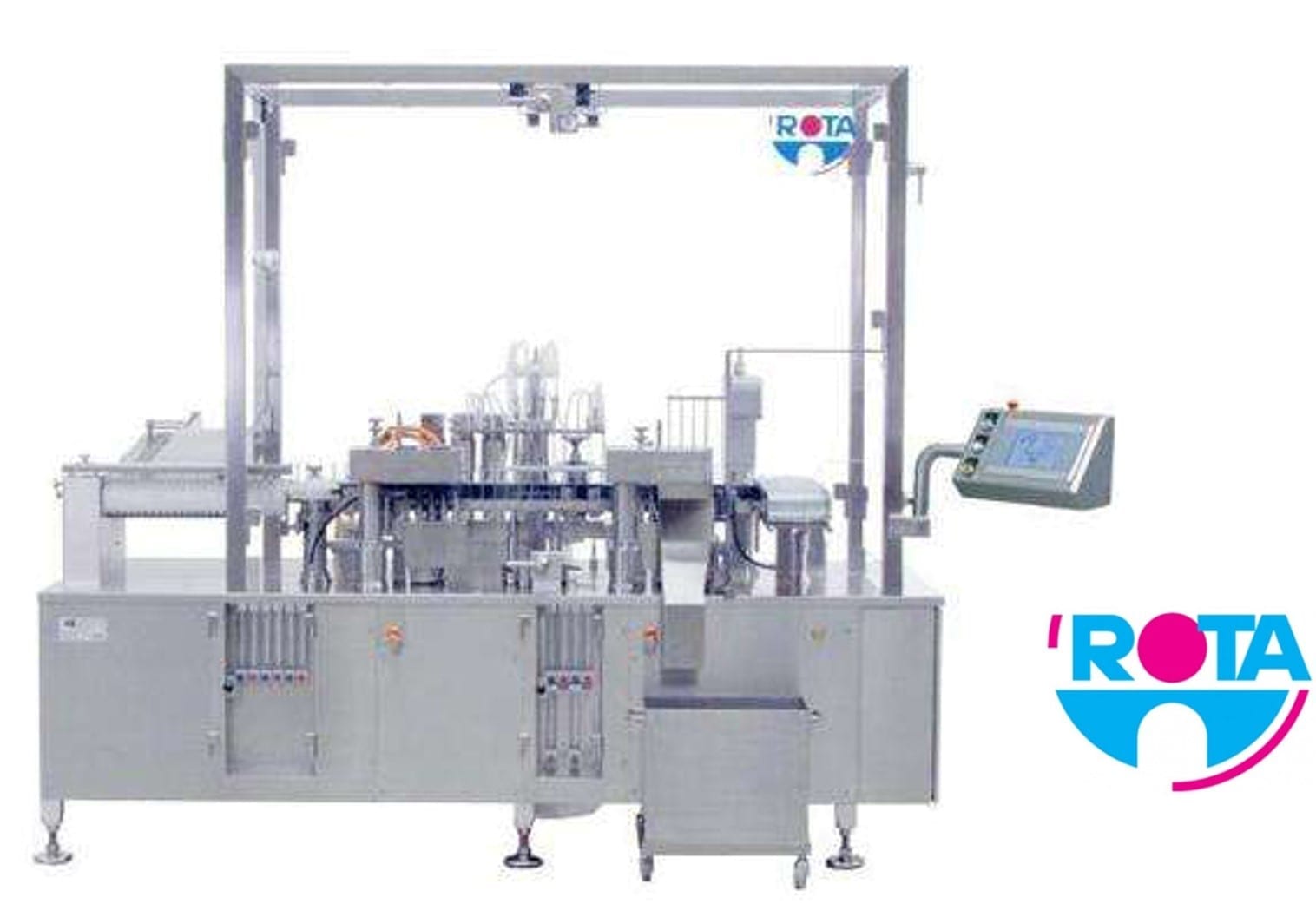

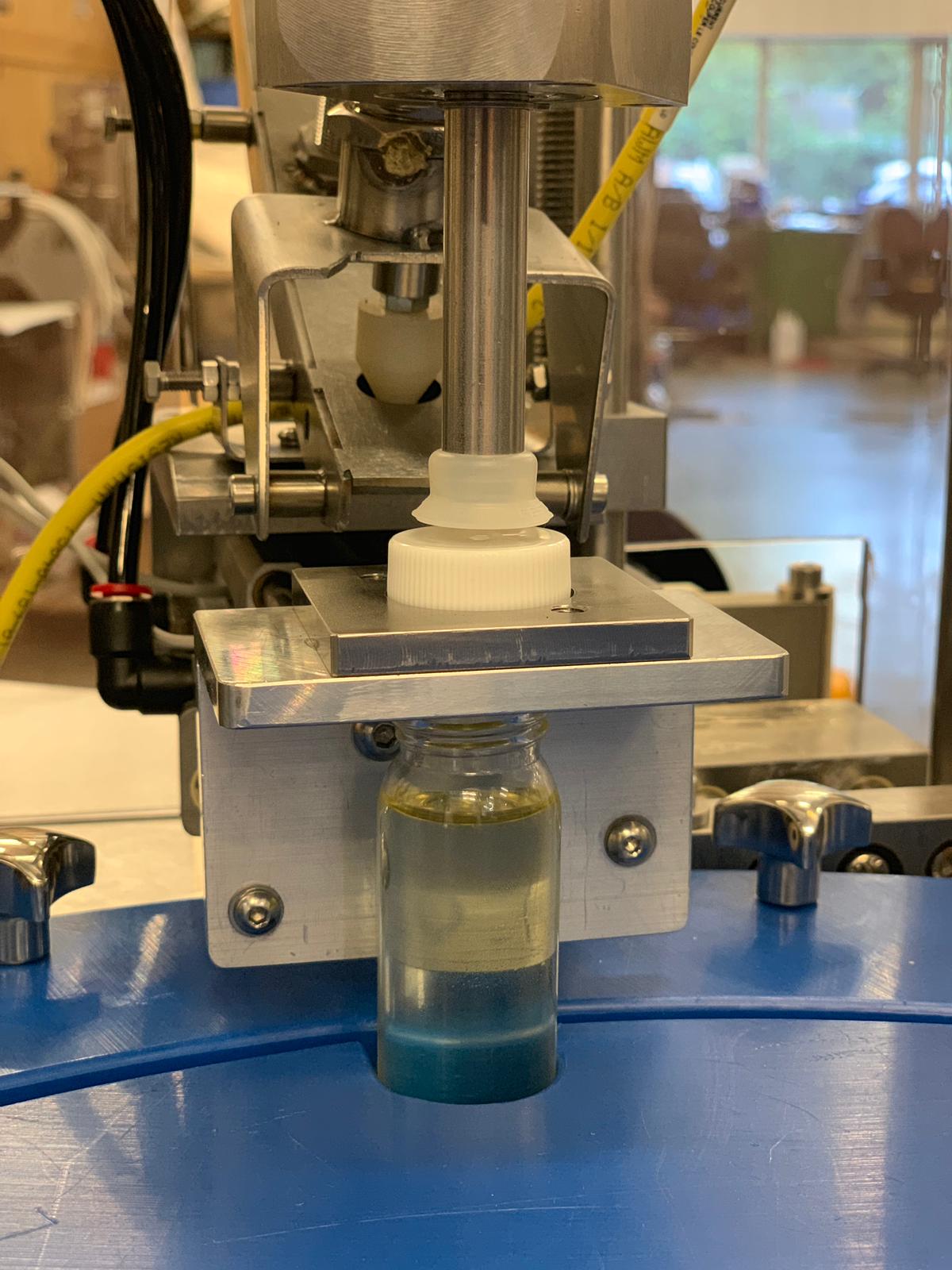

Response Monobloc 1000 Filler & Capper

Reduces Waste, Increases Profitability

Quick-Strip Design Minimises Downtime

Optional Vacuum Capping

Product Specification:

- Fast filling and capping, 15-25 containers per minute.

- Fill volumes from 100ml to 1L.

- Exceptional accuracy of up to ±0.25% reduces waste.

- 316L stainless steel / PTFE pharma and food quality compliant contact parts.

- Compact, space-efficient footprint.

- Fills bottles, jars and screw-top vials.

- Easy-to-use intuitive HMI touch screen controls for your operator.

- Quick and easy to change parts from one fill-size container to another.

- Optional capping under vacuum, to reduce oil leakage from mixtures such as all Nut Butters. This ensures that the product will always arrive with customers in optimum condition.

- Incorporates the Response Benchtop Filler, which can also be independently used if required.

Can include the following elements to give a complete turnkey packaging line:

In-feed table; Bottle blower; Filler; Automatic cap placement; Capper; Labeller; Collection table.

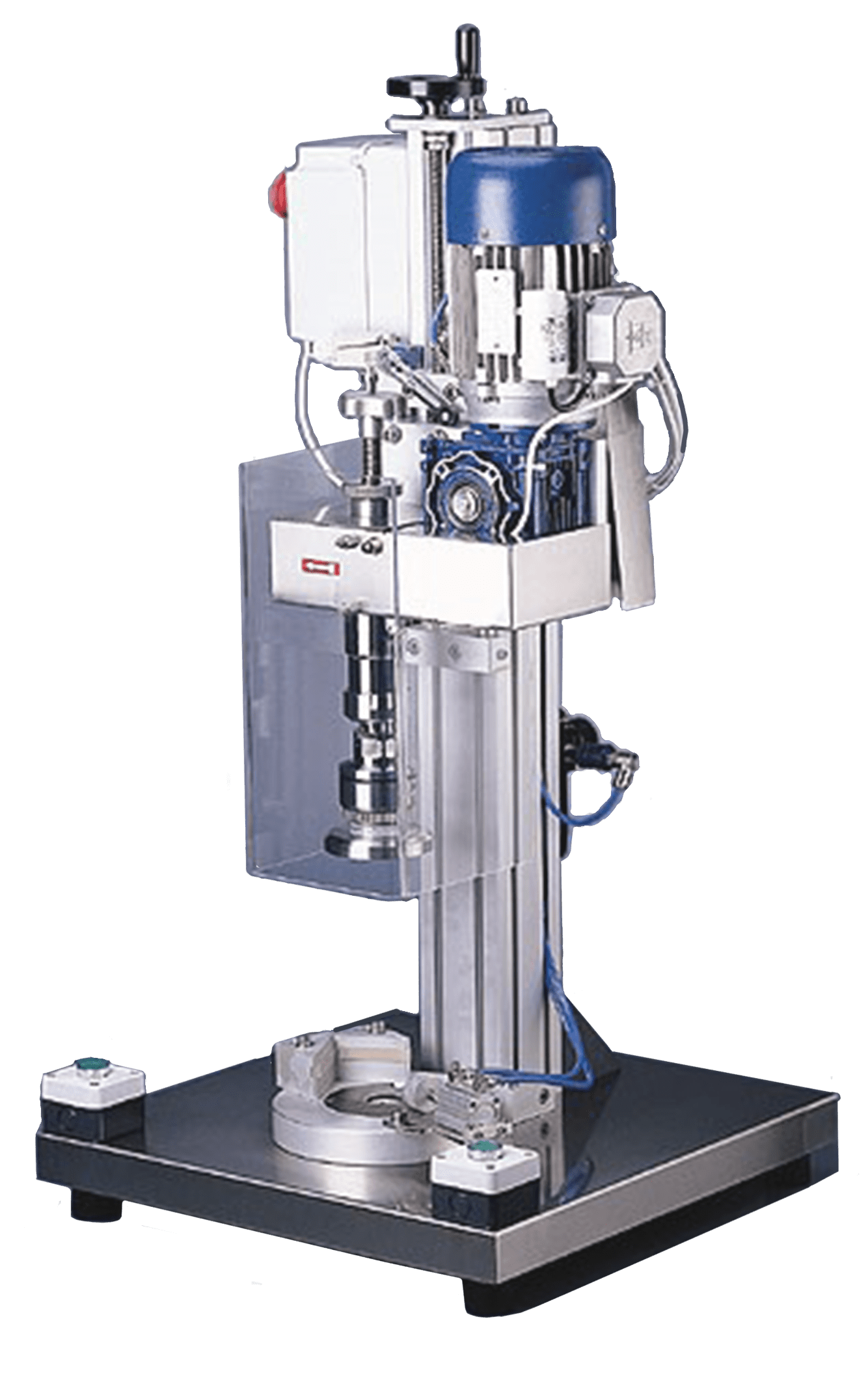

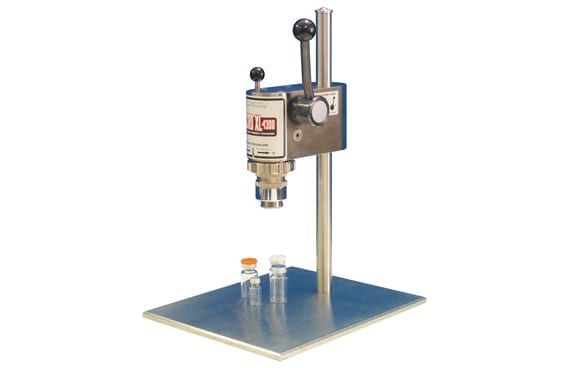

Bench Mounted Capping Station

Quick & Efficient Application

Simple & Intuitive to Use

Make the Most of Your Space

Product Specification:

- A semi-automatic bench mounted unit.

- Compact, space-efficient footprint.

- Efficient application of screw caps.

- Ideal for laboratories or small batch production facilities.

- Includes electronic torque control, a choice of torque heads to suit your requirements, and 360° range allowing quick rundown of multiple fasteners on an application.

Hand-Held Cap Tightener

High Efficiency & Output

Simple & Intuitive to Use

Superior Build Quality

Product Specification:

- A hand held semi-automatic solution, ideal for small to medium batch production runs.

- Application torque can be quickly and easily adjusted.

- Caps are tightened to a consistent level every time.

- Only activates when it senses a positive pressure on the head, ensuring maximum operator safety.

Usually these are fitted to the side of our semi-automatic filling machines on a retractable tether. However, they can also be supplied as stand alone units if required.

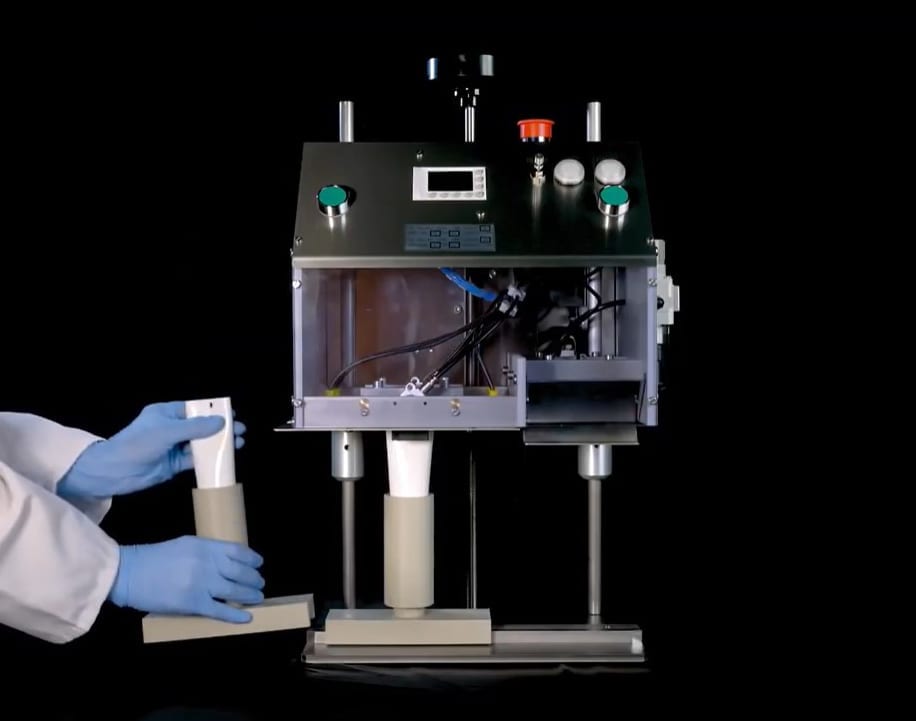

Pneumatic Cap Press

Quick, Efficient & Adaptable

Simple & Intuitive to Use

Up to 600 Containers per Hour

Product Specification:

- Simple and intuitive fixing of press-on lids and caps to glass or plastic bottles.

- Approximate output of 6 – 10 containers per minute.

- Container diameters from 22 - 85mm.

- Maximum container height 240mm.

- Adjustable height and depth to accommodate a wide range of containers.

- Hygienic, durable anodised aluminium and stainless steel construction.

- Bespoke press pads to suit shaped caps can be made to suit your samples.

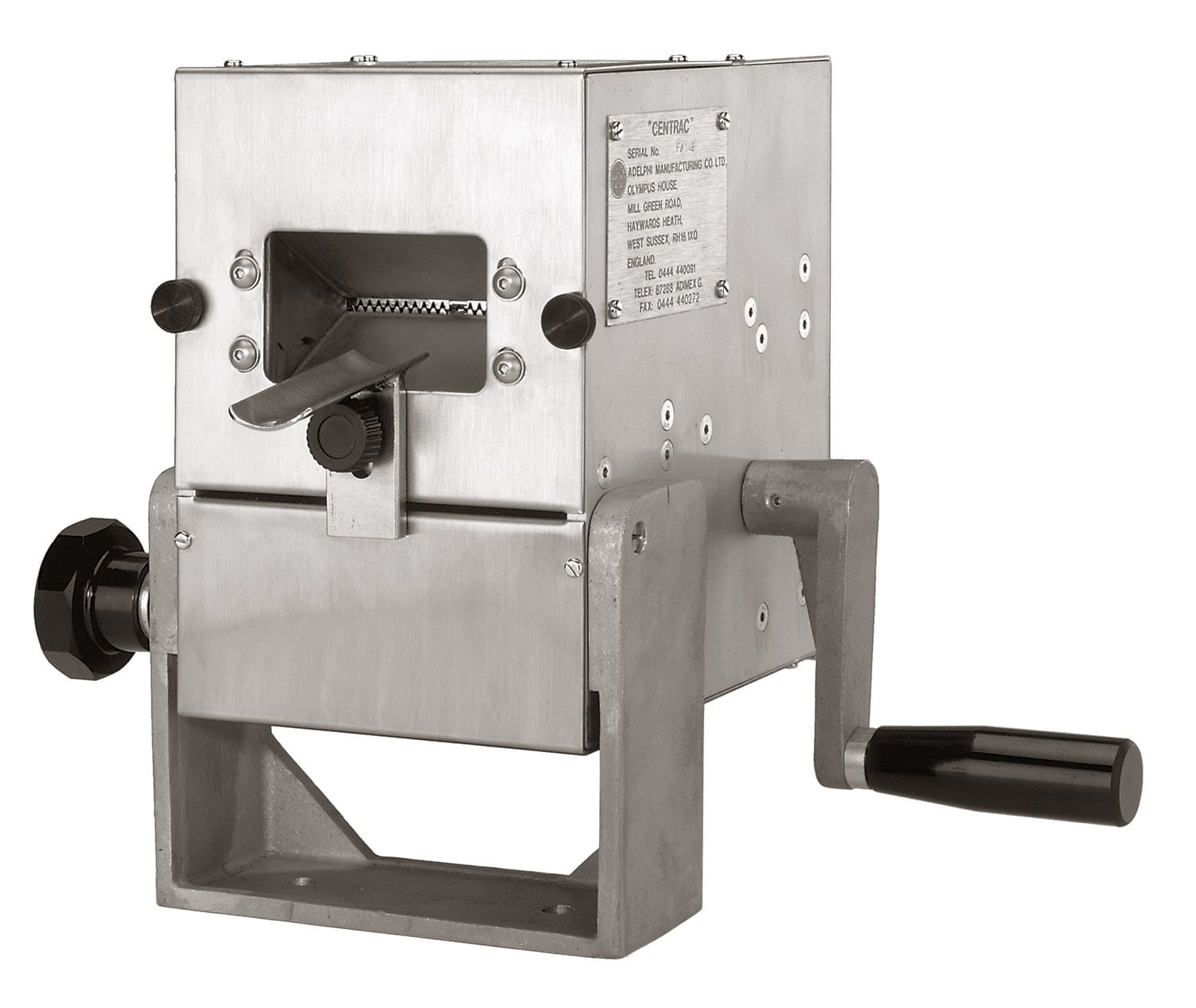

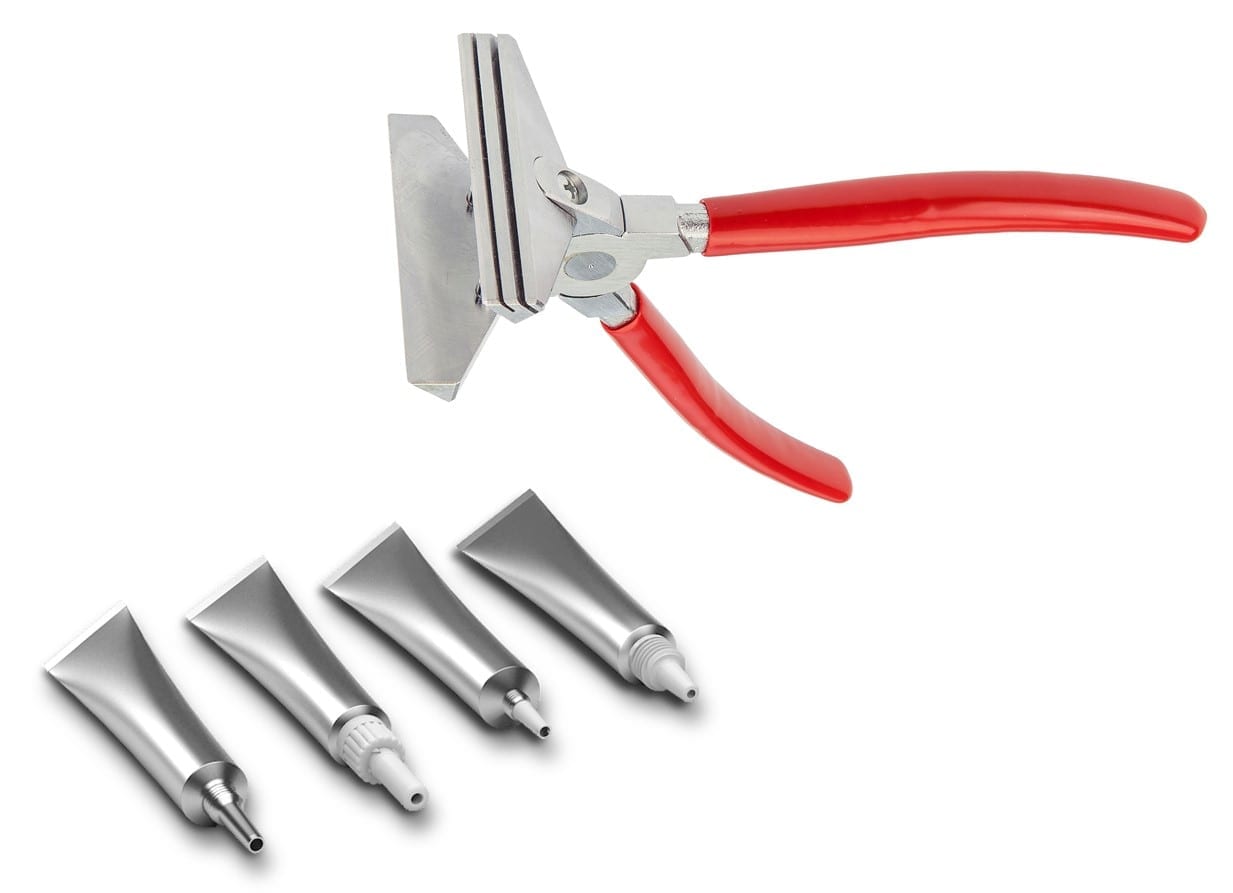

Manual Bottle Cap Press

Quick, Efficient & Adaptable

Simple & Intuitive to Use

Up to 1,000 Containers per Hour

Product Specification:

- A bench top, hand operated, spring loaded machine.

- Exceptional output, up to 1,000/h.

- Bottle sizes: up to 100mm diameter, up to 240mm high.

- Enable easy fixing of press-on lids and caps to glass or plastic bottles.

- Adjustable height and depth to accommodate a wide range of container heights and cap diameters.

OC

OC